All About Mirror Film

Decorative mirror films are used as an alternative to more expensive products that protect against bright sunlight. Such products are especially popular on hot days. Thanks to their use, less sunlight enters the rooms, which affects the temperature regime. The features of mirror films, the advantages and disadvantages of such products, as well as the method of their installation, will be discussed in this article.

What it is?

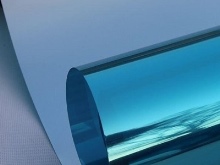

Mirror film is very popular with many people. She found application in many areas. Such a product is a polymer film with a metal coating capable of reflecting light. Such materials can be different in thickness and density, have differences in the degree of light reflection. The canvas, made of polymer materials, is able to protect the room from the sun, while filtering UV rays and infrared radiation. The basis of such a material is an adhesive layer, thanks to which the installation is made much faster and better.

Transparent products with an adhesive surface are used:

- to protect against bright sunlight entering the room;

- for window decoration in homes and offices;

- it is able to ensure the confidentiality of people living in such a room;

- the use of such materials will help make the facade aesthetically pleasing.

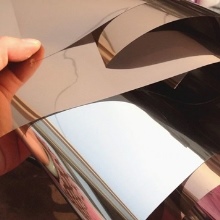

Similar products remain popular among car owners. Thanks to such a film, the car interior is reliably protected from overheating. Placing the product on the windshield protects the eyes of drivers from the blinding rays of the sun and headlights of oncoming cars. Such a film material, which has an increased density, is able to protect glass from breaking, while retaining small glass scattering.

It is worth noting that in some countries, tinting of glass in cars is prohibited, since due to such coverage, visibility at night can be sharply reduced, which leads to emergency situations.

Advantages and disadvantages

When choosing mirror films, it is worth finding out what clear advantages such a material has, and whether it has significant disadvantages.

This product has certain advantages.

- Installing a self-adhesive mirror film allows reduce the penetration of harmful infrared and UV radiation into the room, which has a beneficial effect on health.

- Room heats up less.

- Material use does not allow to see from outside the house what is happening inside the building, while everything will be clearly visible from the room. Such one-way visibility is relevant for people living on the ground floors, as well as residents of high-rise buildings and houses located in the places most visited by people.

- With the right finish the facade will look very attractive from the outside. Such material can be used to paste over not only windows, but also entrance doors, glazing of balconies.

- Using reflective film material will protect the surface from condensation.

- The material will serve as additional protection from heat loss during the cold season.

- Material use prevents fading of wallpaper and fabrics, curtains and other details in the room.

- Also, similar material not combustible, which affects safety in case of fire. And also the film has an anti-reflective effect.

- Sell film in wide rolls, which significantly reduces the number of joints when gluing it.

- She has affordable price.

In addition to obvious advantages, such products also have some disadvantages:

- in the evening, when the electric light is on, the film will not protect the room from prying eyes, which leads to the need to use additional blackout curtains or blinds;

- additional heating rooms in winter through tinted glass does not enter;

- in rooms that are not facing south, the interior can appear gloomy due to tinted glass.

The demand for this product is steadily growing, given the clear advantage of these products over the disadvantages.

Views

According to their functional purpose, self-adhesive mirror adhesives are:

- reflecting sunlight and toning;

- protective or reinforcing;

- energy saving.

There are many modern materials that combine these properties.

Tint film is often made of thin transparent polyethylene... To reduce the light transmittance of such a material, it is coated with a special spray or painted. When choosing a product, you should take into account that metallized models are preferable to painted ones. They have a large resource, while they shine much more. And since metallized coatings do not have a stain, this affects the view from the windows. A painted coating can change its appearance a little, making it less realistic.

In the production of film reflective materials, they are more often used PVC (polyvinyl chloride). Such products can be divided into certain types, differing in the method of their manufacture or materials.

Calendered

Inexpensive models include calendered film. Cheap monomeric PVC is used in its production.... A calendered film is produced by rolling the product through special rolls called calenders. The quality of such products does not always satisfy consumers, since such a film shrinks and deforms. These products are usually classified as economy class.

Cast

In the production of cast models, higher quality PVC (polymer) is used. In contrast to the previous version, cast products can maintain their size for a long time, they look more elastic. Even in adverse weather conditions, their service life can be more than 10 years. Cast film can be used to paste over surfaces of various shapes. Using this option allows you to get a guaranteed 100% result. Cast models are of higher quality. Such products are not prone to strong shrinkage, they are plastic, so they will not tear as quickly as calendered models.

You can also find calendered models in the production of which polymer PVC is used. Such products are a cross between the options presented above. Although these items may shrink, they will not shrink very much.

Sun protection mirror film for windows can be two-layer and three-layer. The surface of such products is glossy or matte.

Mirror film is also classified depending on the purpose.

- Architectural decorative film... It is used to decorate glass facades.

- Energy saving... Used to preserve heat and reflect heat energy.

- Sunscreen... Such models are capable of absorbing up to 99% of the bright rays of the sun.

- Vandal-proof... The presence of a thickened polymer layer can significantly complicate penetration into the interior of a car or any room.

The coatings have a different degree of toning, they are also different in shades - the products have a variety of colors.In the production of the metallized layer, raw materials such as aluminum, bronze, titanium and nickel can be used.

Design

The interior uses a mirror film of different colors. It can be gold, black, blue, as well as gray, blue. A large selection of such shades will allow you to find the most suitable option for each specific room. Mirror glass from the street looks very interesting and unusual.

- In cases where the windows are low, you can look in them, as in an ordinary mirror.

- The mirror sheet is suitable as a replacement for a conventional indoor mirror.

- Mirror sun-protection film is often used as a decoration when decorating a French balcony. In this case, the lower glass can be pasted over with colored tinting.

- The attractive appearance of such products will look perfect on the glass surfaces of windows, loggias or balconies.

- Sheets of stained glass film will decorate glass interior doors, they can be used to decorate wardrobes.

A large assortment of similar products and a variety of types will allow you to find the best option by choosing a color that suits a specific interior.

For the decoration of the facades of administrative buildings, country houses, it is better to choose dim shades of such products. In this case, it is more appropriate to choose a metallized film with a bronze color with a one-sided visibility of about 10%. From the side of the street, such a film has a bronze color, but inside it is silver. Such a coating does not transmit ultraviolet rays, and there will also be no glare from the light inside the room.

Applications

Mirror protective films have become an indispensable thing for window decoration in multi-storey buildings and offices, they serve as excellent protection against bright sunlight entering the room. The scope of application of such products is diverse. Decorative films can be used:

- for pasting glass;

- for decorating doors, cabinets and other flat surfaces;

- to decorate the ceiling and walls.

PVC products are perfect for decorating ceiling and wall surfaces. It is worth noting that decorative film coating on the ceiling in the form of appliqués or rosettes looks unusually stylish.

The canvas, which does not have a layer of glue, is used for stretch ceilings. Such a coating, unlike models for glass surfaces, is not transparent, so it can be used to hide pipes, fixtures, and electrical wiring. The disadvantage of such canvases is that when the air temperature drops, they become brittle and begin to break. Based on this, it is advisable to use them indoors.

PVC films can be mirrored or stained glass. Metallized mirror film can be transparent or opaque. It is usually chosen when pasting windows with a large area. Stained glass models are more often used in car tuning.

In addition to thin films of PVC and other plastics, other materials are produced that are used for decorating glass surfaces. Sheets are usually produced with a thickness of up to 2 mm. Stick them on a perfectly flat plastered surface. This canvas can also be used as a replacement for a conventional mirror. This self-adhesive film can be installed on any surface; it does not need to be fixed on the wall in a special way. Using this option instead of a mirror will allow you not to fear for damage and breakage of glass.

Thanks to this coating, the interior will become more interesting. The presence of additional mirror surfaces will ideally move the walls apart and increase the space, make the room visually more spacious and bright.

At the same time, a safe film coating is perfect for families with small children.

How to stick?

If you need to stick a mirror film on the surface, you can do it yourself by performing certain actions.

- It is necessary to prepare the windows. To do this, they must first be washed and cleaned of dust, then dried thoroughly. Alcohol-containing agents are used to degrease the surface.

- Should measure the size of the window, and cut the film.

- Cut the filmusing a clerical knife, scissors or razor blade.

- Make a solution of water and soap, moisten the glass with it.

- From the film follows remove the protective layer.

- The product is gently applied to the surface... Using a roller or spatula, smooth the film from center to edge.

- Parts that do not match the size of the windows, need to be cut with a sharp knife.

Care Tips

One of the clear advantages of toning agents is that they do not require special care. Detergents are used to clean the products. It is important that they do not contain abrasive particles that can scratch the film. And you should also make sure that there are no chemical compounds. When washing coatings, do not use alcohol-containing products.

A hairdryer is used to remove the old film. Hot air should be blown over the coating, then remove the remnants of the film with a scraper. After dismantling, the glass should be thoroughly washed with soapy water.

In the next video, you will be gluing a mirror film on the windows.

The comment was sent successfully.