Sharpening circular saw blades

The correct choice of the angle of sharpening of discs for a machine tool or for a circular saw is an important component of success when performing all operations yourself. Restoration of the sharpness of the teeth in this case is of particular importance, the master has to act very carefully. It is worth talking in more detail about how to properly sharpen a saw blade with soldered wood with your own hands.

How to determine wear and tear?

The decrease in the quality of the cutting element is largely associated with a decrease in the sharpness of its teeth. The sharpening of circular saw blades must be carried out in a timely manner, before deep damage appears, making restoration impossible. Determining the signs of wear is a task that requires special attention from the foreman.

Sharpening is necessary if the tool behaves in a special way.

- Heats up strongly, smokes. A dull saw blade increases the load on the engine. When overheated, it begins to generate heat intensively, smokes, and may even fail.

- Requires increased pressure. This feature applies mainly to models with a mechanical type of material supply. If you have to use more force than usual when cutting, it is worth checking the sharpness of the cutting blade.

- Leaves traces of carbon deposits, oils, and a specific unpleasant odor on the workpiece.

Any of these signs, identified during the operation of the circular saw, indicates that it is time to replace or sharpen the blade. The degree of wear can be determined more accurately only by removing it from the tool.

Sharpening principles and angles

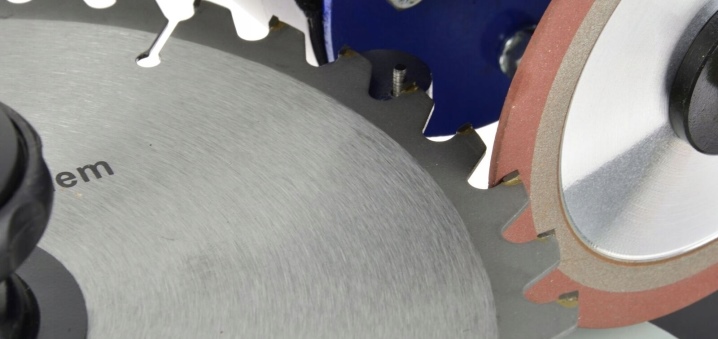

The cutting teeth in the design of the circular saw blade have 4 planes: 2 side, front and rear. According to their form, all these elements are divided into several groups.

- Straight. Such teeth are in demand when sawing materials in the longitudinal direction, at speed. The quality and accuracy of the cut are not particularly important.

- Oblique. Teeth of this type always have an inclined plane offset to the left or right. Most often, such elements alternate on a disc, the edge is called variably beveled. For different types of materials - wood, plastic, chipboard - a certain angle of inclination is set. It will be maximum when cutting chipboard, and the option of tilting the front or rear part can be used.

- Trapezoidal. Such teeth on a circular saw blade have 1 big advantage - they slowly dull. Usually on the cutting edge, they are combined with straight ones, located above them. In this case, the trapezoidal elements will be used for rough work, and the straight ones will help to achieve a clean cut. Such discs are used in the processing of polymer sheets, MDF, particle boards.

- Conical. They are also auxiliary, used on discs for cutting laminate and other fragile materials. The special shape of the elements protects the surface from chipping and other damage. The leading edge of tapered teeth is usually straight or concave and is good for fine sawing.

Depending on which type of teeth is used on the saw blade, a suitable sharpening angle and other parameters are selected. It is strictly forbidden to process all elements under a general slope, without taking into account the individual characteristics of each element.

Each saw blade in a circular tool has 4 main corners that require sharpening. They determine, along with the shape of the tooth, the features of the geometry of the cutting edge. For each individual element, it is customary to measure the cut angles of the surface and directly the front, rear parts.

Depending on the type, purpose, mass of the saw, possible options are distinguished.

- For rip sawing. These discs use a 15-25 degree rake angle.

- For cross cutting. Here a rake angle of 5-10 degrees is used.

- Universal. In this case, the tool teeth are sharpened 15 degrees in the area of the rake angle.

The type of processed material also matters. The harder it is, the less should be the indicators of the selected angle. Softwoods can be cut at a wider incline.

When using carbide discs, wear can be seen literally with the naked eye. In this case, the front plane is erased more intensively than the back.

What is required?

Sharpening a circular saw blade is possible only using special tools. To increase the accuracy during work, specialized machines are used, which greatly simplify this process. And you can also use more primitive tools - a file and a vice for fixing, as well as a piece of wood.

How to sharpen?

A circle with victorious solders or a regular wood disk for a circular saw is quite you can sharpen it yourself, restoring the sharpness of the teeth. True, many factors will have to be taken into account when carrying out work. They can influence the choice of sharpening method - manually or using a machine. Higher precision is provided by mechanized processing, but you will need to purchase special equipment for it.

Manual disc sharpening

When choosing this method of restoring the sharpness of the teeth on the saw blade, use the available tools. It is only important to prepare a special flat-shaped stand. It will avoid the need to hold the disc in your hands and will protect you from injury.

The following requirements are imposed on the stand:

- coincidence on the level of the axis with the processed surface;

- the possibility of positioning the toothed circle in a perpendicular plane;

- swivel joint.

The stand serves not only as a fastener - it allows you to sharpen the teeth of the saw blade at different angles, guarantees injury safety when performing work. Preliminary marking of the surface with a colored marker will help to achieve higher accuracy. Additionally, a vice is used, with which the circle is pressed against the stand.

A grinder will help to facilitate the sharpening process itself, but experienced craftsmen eliminate minor bluntness with a simple file.

Multidirectional teeth require machining from 2 sides of the wheel... In this case, the disc is first fastened horizontally with the marked side, then turned. Actions are repeated. If necessary, you can change the angle if sharpening is performed on a disc with a mixed type of teeth.

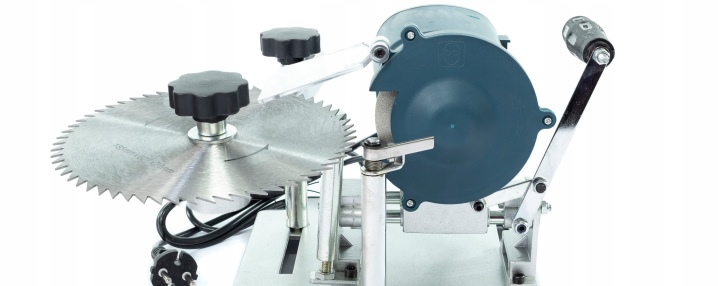

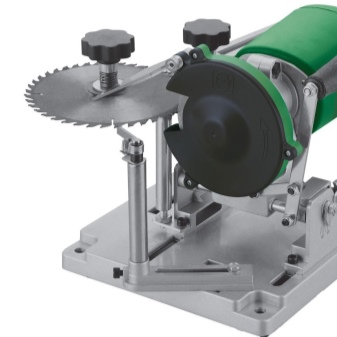

Using a grinder

With the availability of special equipment with a manual or electric drive, the problem of restoring the sharpness of the teeth on the saw blade is solved quickly and easily. Special grinding machines have compact dimensions, are quite mobile and functional. They can be adapted for use in the home workshop.

It is necessary to choose a machine for sharpening circles for a circular saw, be sure to pay attention to the material of the abrasive used. The best options are made from:

- silicon carbide (green);

- elbor coated with diamond powder.

It is important to consider that carbide discs are difficult to tool sharpening.

Variants with victorious spraying, other complex elements as a coating can also cause problems during operation. Even with a machine, it will be difficult to guarantee successful sharpening.

Working with grinding equipment is as simple as possible. The master only needs to fix the prepared disc on a special support with a latch, then perform several actions.

- 1 tooth is marked with a marker or chalk.

- The required angle is measured at which the processing is performed. If there are no special requirements, a universal slope of 15 degrees is chosen.

- Start sharpening by cutting from 0.05 to 0.15 mm. Treat each tooth in succession so that it acquires the required sharpness.

When sharpening carbide discs, we recommend grind metal on the front and back surfaces of the teeth at the same time. With common steels and alloys, less effort can be dispensed with. Enough sharpening just the front.

When working with a victorious disc, you must first be sure to free it from dust and dirt. It is important not to expose it to mechanical stress, only to remove foreign inclusions. In this case, the working planes of the teeth are processed sequentially. You cannot spend more than 20-25 times in one place. The machine usually removes a blunt edge in literally 1 pass. As the disc is worn out, it is simply replaced with a new one.

For an illustration of how to sharpen a saw, see below.

The comment was sent successfully.