What are vibrating tables?

For the manufacture of various construction and production components, it is important to seal the composition used. In this case, the vibrating table comes to the rescue - an effective and multifunctional equipment. This device can be made by yourself or purchased from a specialist retailer.

Appointment

Vibrating table is a highly specialized equipment used for the production of various structural building elements. The device is perfect for the manufacture of paving slabs, decorative stone or blocks of any complexity.

In addition to the production of the above-described parts, using a vibrating table, you can:

-

mass produce products that require the use of the vibration method;

-

produce durable and high quality indoor tiles;

-

to ram cement or asphalt concrete products;

-

use a cleaning method, which is especially important for sifting sand;

-

to seal structural and functional elements of fences or window openings.

In addition to the above purposes, the vibrating table allows you to efficiently and quickly press various decorative products, therefore, this device is highly useful for jewelers. Due to the unique vibration properties, the equipment is also used in the food industry, for example, for chocolate, or for tempering any other product.

Regardless of the purpose of the vibrating table, its efficient operation is possible due to the presence of vibration effects on various surfaces... This allows the structural performance of materials such as concrete or asphalt to be improved. Based on practical use the presence of such vibrations has a positive effect on the appearance and strength of the manufactured products.

Device

A vibrating table or platform is a sophisticated high-tech equipment consisting of several structural elements. They are all interconnected.

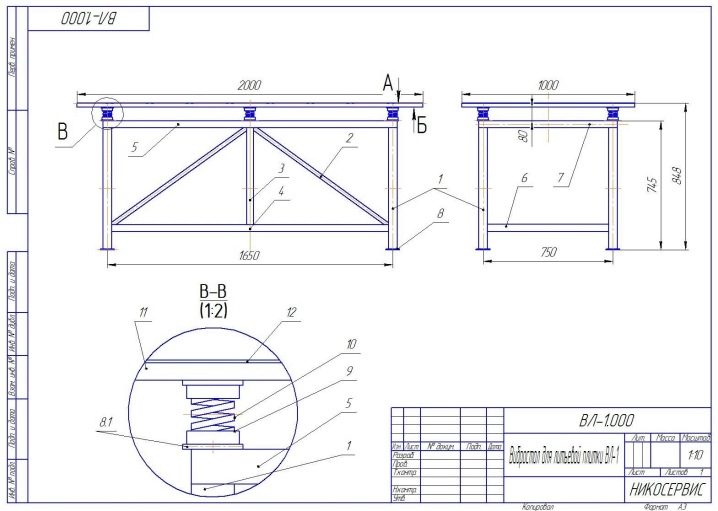

Detailed description of the structural parts of the vibrating table.

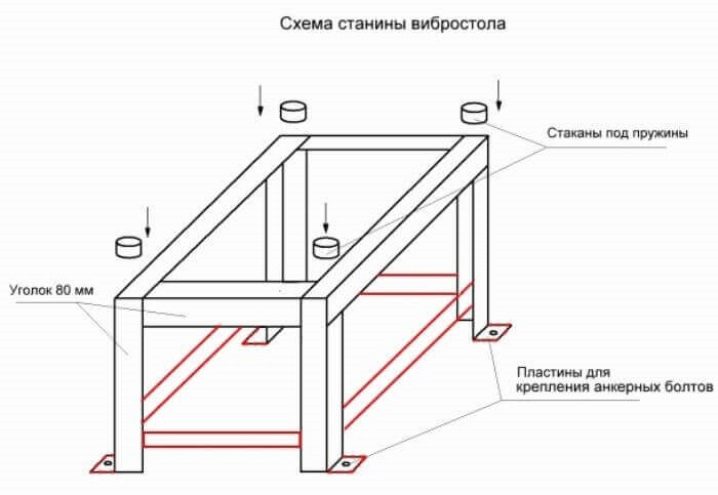

- Support bed. This element is manufactured from a high-strength metal frame.

To ensure maximum stability and efficiency of the process, the main structure must be massive and sufficiently rigid. Otherwise, significant fluctuations are observed, which indirectly affects the accuracy of the production process.

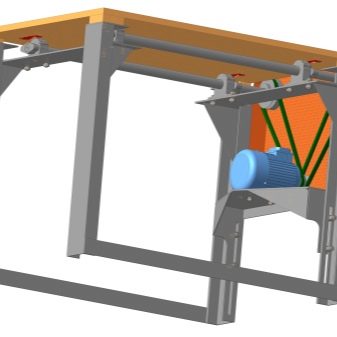

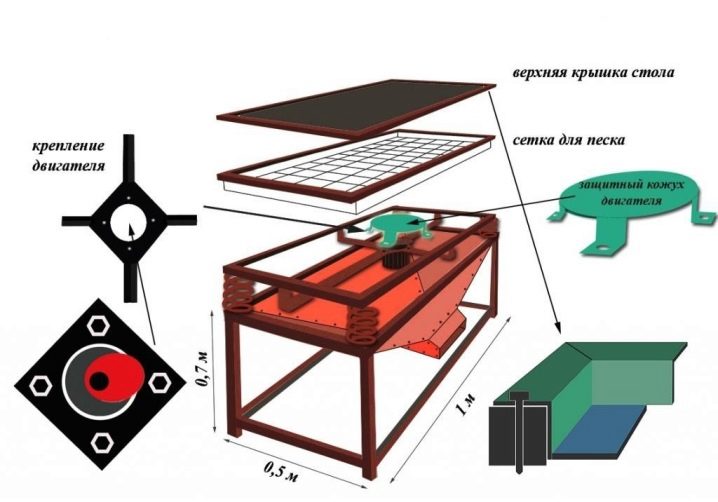

- Working platform. It is a smooth worktop in a horizontal format. In most cases, the internal platform mountings are movable, which allows you to extinguish most of the energy. The main fasteners are rigid springs in the amount of four pieces.

It is important that the table top is distinguished by the maximum smoothness indicator.

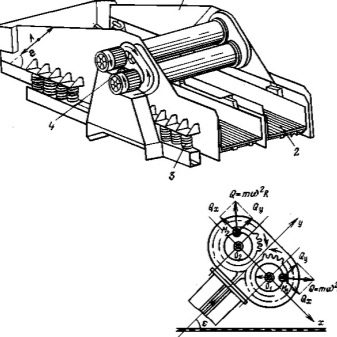

- Drive mechanism. It is presented in the form of a slider that is securely attached to the bottom of a metal plate - the main structural element of the vibrating table. With the help of the motor, rotational movements are made towards the eccentrically attached weight. This feature allows much more efficient damping of various vibrations on the table surface.

- Starting device... There are two main elements in this design - the start and stop buttons.When connecting the equipment, a relay of current and thermal type is used, which effectively protects the equipment from unnecessary overloads.

The aforementioned structural elements allow to achieve an insignificant degree of vibration of the equipment, and also provide the most uniform distribution of kinetic energy over the entire area of the tabletop.

The main parameters that have a significant impact on the efficiency and productivity of the vibrating table are engine mainshaft speed and amplitude percentage for oscillating motion.

In addition to the above-described components, the vibrating table also contains a main plug for power supply, rubber mounts, a socket for connecting to an electrical network and specialized vibrators of an electromechanical type.

Views

The vibrating table is a sophisticated technical equipment, which is presented in various variations and varieties. These devices are conventionally classified based on several factors.

- Dimensions and area of the desktop surface... The larger the desktop, the higher and more productive the technical characteristics of the equipment. An increase in the indicator allows you to simultaneously compact several forms or products.

- Actual power... The factor by which the performance of the equipment used is determined. Depending on the mass of the products to be placed, one or another motor is selected for the vibrating table. With the wrong choice of motor, the efficiency of the device is significantly reduced.

- Amplitude of vibrations. In the presence of a device that is capable of adjusting the frequency of vibration exposure, the operator of the equipment is able to quickly switch the vibration table to one or another mode of operation based on the use of certain materials or purpose.

To meet certain needs of the client, manufacturers produce two main types of vibrating tables: forming and demoulding... The first type is more versatile and is mainly used to seal certain products using vibrations.

The demoulding variety is an industrial type of equipment in which the creation of certain products is carried out using small specialized nozzles. In any case, finished products are produced from so-called molding containers.

How to choose?

The quality of production work and the functional characteristics of the equipment directly depend on the correct choice of the vibrating table. Experts identify the following indicators that need to be paid special attention to.

- Working surface. The vibrating table must quickly process the declared surfaces of various sizes and shapes, therefore, before purchasing the equipment, it is necessary to take into account the dimensions of the main tabletop. And also you should pay attention to the material of the working part. Manufacturers produce such devices from ferrous metals, aluminum or stainless steel.

In order to work with the equipment more conveniently, it is necessary to choose a vibrating table with additional sides on the sides.

- Remote Control... The presence of a remote control panel allows you to increase the functional properties of the equipment. With its help, the operator of the device can set the operating time, turn off the vibration table, or change the characteristics of the amplitude and vibrations.

- Vibrator... The main requirement for the internal vibrator is the presence of evenly distributed vibration, which increases the efficiency and productivity of the equipment. The power supply of the network is usually selected 220 V or 380 V, depending on the characteristics of the electrical network.

To provide the device with the maximum possible performance, special attention must be paid to such indicators as the structural properties of the eccentric, the attachment point of the main drive and the equipment of the working platform, depending on the declared power.

How to do it yourself?

Before making a vibrating table with your own hands, it is necessary to take into account all the design features and parameters of the future product. One of the most important pieces of equipment is the vibratory compactor. It can be done in fairly simple ways.

- Forming device... The main purpose of this element is vibration ramming of concrete mortar, which is pre-poured into a cast mold.

- Deforming equipment... Designed for quick and efficient removal of solid products from special molds. This action is carried out using a specialized device.

- Non-standard ideas. They are used for the production of a limited amount of a particular product, outside of industrial practice, at home or for a small private enterprise.

To ensure that there are no mistakes in the manufacturing process of the vibrating table, it is necessary to monitor the vibration adjustment and attach the main structure to the floor as securely as possible. And also you should pay attention to the quality of the welding seams and the horizontal position of the tabletop.

Preparation of materials and tools

To make a vibrating table yourself, you need to prepare certain tools and materials in advance. Without them, further work on the manufacture of the table is devoid of the slightest sense.

To create functional equipment you will need:

-

metal pipe for the production of glasses;

-

springs for vibration table in the amount of 4 pcs. to create movable supports;

-

steel sheet, the thickness of which is 8 mm, for the countertop;

-

rolled metal type for fast welding of structural elements;

-

fasteners for effective fixation of the vibration motor;

-

an engine with a power of 1 kW;

-

a specialized apparatus that allows electric welding.

In addition to the tools described above, you also need to purchase an electric drill, a metal grinder and a housing used to install the control panel and additional equipment.

Drawing creation

The development of a drawing for a vibrating table is a particularly important process on which the success of the equipment implementation depends. To avoid various mistakes in the manufacture of the device, you can use proven documentation, or start creating a sketch yourself.

As practice shows, the optimal dimensions for the work surface are 50x100 cm, while the distance from the table top to the floor cannot exceed 80 cm. Otherwise, there is a decrease in the efficiency of the equipment.

In the process of creating a drawing, you need to know about some of the features.... For example, the surface of the table top should always be in a horizontal plane, while the legs of the frame cannot differ in length. And also it is worth paying attention to the fact that the engine should not touch any metal elements or the base itself.

Motor selection

One of the simplest options for making a vibration table is to use car ramps. To do this, you should prepare 3-4 slopes, a construction hammer and a wooden shield. Compaction occurs during the installation of previously prepared forms on the shield, which is mounted on a base of tires.

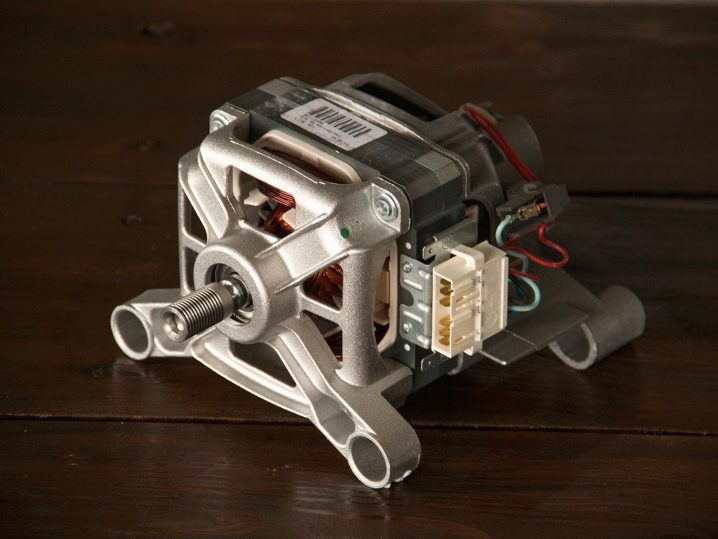

In addition to the above manufacturing method, you can create a vibrating table at home using electric motors from a hammer drill or drill. In this case, a metal base is used, which is placed in a horizontal plane.

The compaction of the material used is due to the conversion of kinetic energy with an electric motor. In addition to the motors described above, you can also use an engine from a washing machine for a homemade vibrating table. In this case, special attention must be paid to the shaft bearings and the fixing of the equipment in the plane.

Assembly

The first thing that needs to be done to assemble the finished product is to mark the used metal structure according to the developed drawing. And you should also cut the blanks.

Further step-by-step process of creating vibration equipment.

-

Welding of a platform from a metal profile in accordance with the selected dimensions.

-

Fixation of special thrust bearings for installing the frame to the uprights.

-

Adding a rectangular base to the legs of the main frame.

-

Installation of stiffeners and inspection of welded joints.

-

Installation of additional cup holders to increase the diameter of the external springs.

-

Reinforcement of the table top with stiffeners.

-

Welding of cup holders for springs.

-

Installing and fixing the vibration motor.

-

Assembling the frame and platform in accordance with the drawing.

After completing the above steps, you need to connect the power cable and conduct a test run of the equipment. The analysis of functional systems is carried out using a weight that is adjusted using an eccentric device.

How to make a vibrating table with your own hands, see below.

The comment was sent successfully.