Everything you need to know about slings

Slings - a material that allows you to lift and move loads of increased tonnage with its inherent smoothness... Swaying, for example, of a stack of bricks is not excluded. With the help of slings, you can lift and carry an object much larger in size than a pipe or a bundle of reinforcing rods.

What it is?

The slings are wrapping loops, are used in an amount of at least two, since one loop can only move a single simple structurefor example a T-welded assembly of pipes of the same diameter. To move, for example, a brick pile - several tons of bricks laid in "cubic" masonry on a Euro pallet, two items are required. To move, for example, a reinforced concrete large-panel building block, you may need 3 or 4 slings - the hook on the loop is hooked onto the steel lugs embedded in the separately taken concrete products.

In addition to the cable, braided tapes and belts, ropes, a load mesh or a panel are used for sling products. A hook, bracket or ring is attached to the end of the lanyard.

Views

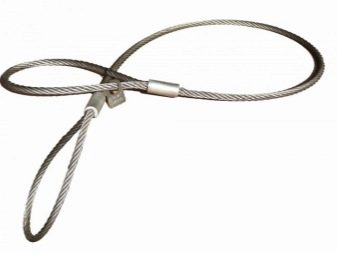

A rope for lifting loads - a sling with loops at the ends. One end is hung on the hook-shaped lugs of the workpiece or block being moved, the other - clings to the rope hook on the crane.

According to GOST, metal and synthetic ropes are allowed. They are used to secure the stack before lifting with a large loop. So, in cases where a Euro pallet with bricks is clasped by a larger loop, several times smaller is hung on the pulling hook of an auto- or tower crane.

There are chalki with already threaded rings or hooks. The hook on one of the loops is wound behind the lug of the workpiece, and the free, second, loop is thrown onto the crane hook. If hook-shaped lugs are used (not a loop or ring hooks), then, on the contrary, instead of a boom loop, a ring tightened into the same loop can also be put on it. Knots in all cases are knitted not ordinary, but, for example, sea, fishing.

The main safety requirement is that the rope / rope should not suddenly untie: a drop of a load of several tons from a height of more than ten meters to the construction site would lead to serious damage, including human losses.

The bark-protective product is a reinforced tape loop fixed to a tree. At its ends there are loops, the starting material for which is a woven bark-protective fabric. It is very resistant to abrasion from contact with the bark of a tree, due to the resistance of which such a device is used in combination with a winch that helps to pull a stuck car out of the fiery mud. This allows you to free the car itself from the dirt, and not damage the bark of a perennial tree, behind which the sling is wound.

At the same time, the tree must be reliable enough for the car owner to be able to prevent it from falling onto the car.

Load slings do not have the function of protecting the bark from damage. Their requirement is to ensure the reliability of the grip of the transported goods so that they do not slip out during the transfer process, which would lead to additional damage caused at the facility under construction. For dismantled old buildings, this requirement is met only for safety reasons for builders working near a facility that has just been demolished with a directional explosion.

The lanyard element, being a rigging product, is supplemented with a metal or synthetic extension.

If the load is large enough, an extension with hooks will be needed for each of the line elements. For example, in order to move a multi-ton stack, consisting of rolls of roofing material, wallpaper or other luggage, the material of which is rolled up and placed in blocks in a special carrying box, the standard length of the sling product may not be enough. For example, when you need to move a stack of rolls of the same roofing material, consisting of blocks laid on separate supports, and the length of the sling does not exceed 2.5 m with a stacking meter of 5x5x5 m, then extension cords with hooks may be required. The connection diagram of the sling elements is as follows.

-

The loop of the sling grip with a free (smaller) loop clings to the hook of the extension cord.

-

The opposite hook of the extension hooks onto the lanyard with small loops.

-

The second sling component is suspended on the larger hook of the cable tensioner on the crane.

As a result, a kind of cascade is formed, consisting not of one, but of three levels, the intermediate in which is the tightening element with hooks, and the two extreme ones here are loop (loop) ones.

Shops selling rigging and cargo equipment for the transportation of bulky luggage offer all kinds of textile and metal slings of rope-cable and tape design. According to the execution, the slings are divided, for example, into the following varieties.

-

STK - textile ring sling.

-

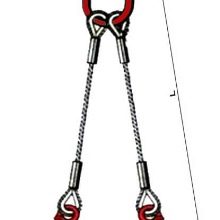

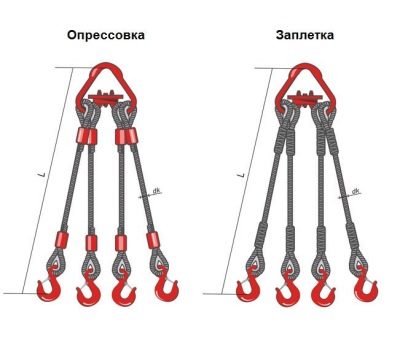

Branched options: 1SK - one-branch rope sling, 2SK - with two branches, and so on.

In addition to these varieties, for example, looped textile (STP), 3SK, 4SK and several other varieties are actively used. The permissible load capacity is indicated on the product tag, therefore it is forbidden to exceed this parameter when trying to lift an excessively heavy load: such attempts always end with a rupture of the loop structure or the entire sling, decoupling of the nodal connection of the looped parts, breaking the hook (if an extension cord is used). Even if the product can withstand one session of such "overvoltage", it is considered unnecessarily stretched and is excluded from the further process of loading and unloading or installation work.

The so-called auto-lanyard has found a special application - an auto-grinder to be thrown onto the transported cargo, like a lasso, in places with difficult access, as well as in cases where it is necessary to grab packages with cargo.

Cable cars

Rope weaving involves the use of a regular rope. A ship or aircraft rope has a good margin of safety. Hooks are already attached to such products, ready to go. Such a product is manufactured according to the standards GOST 25573-1982. Instead of a hook, a carbine can also be used.

The ambient temperature of the steel (non-synthetic) rope when using ropes is from -40 to 400 Celsius. The rope is made mainly of wire braided into daughter ropes (strands).

Rope weaving makes it more accessible to detect premature abrasion, which in turn serves as a warning for further use of such a device under constant and regular loads.

Examples include the following samples.

-

1 m of single-branch rope product will withstand 32 kg.

-

Slings of 10 meters, designed for a ten-ton load.

Rope products are manufactured using the following technologies.

-

The element is pressed using an aluminum sleeve.

-

The sling element is woven manually.

Slings with one, two and four legs are mainly used in warehouses and in production halls... The rope branch has end elements that are closed by braiding or crimping (turning). The annular sling element is in direct contact with the load.The loop product is thrown onto the hook; due to its quick actuation, this variety is widely used in various sectors of the national economy.

Chain

The basis of such an element is a chain, the links of which are welded. This variety is designed for sharp-ribbed luggage. In addition to greater strength, the user gets a disadvantage - massiveness: the links of the chain, each of which weighs more than one kilogram, is not easy to move. Advantages, along with a high level of workload - ease of repair: a damaged link can be easily replaced by sawing adjacent ones. After replacing the damaged link, adjacent links of the same chain are welded.

Chain slings are divided into one-, two- and four-leg... The latter species is called the chain spider. Under critical load, the chain links can stretch but remain intact. A chain branch is used to restore a product during a planned repair. The ring chain product, called the universal chain, has found application in the movement of loads under near-limit operating conditions. The ring product will not be damaged when moving luggage with sharp edges. In addition to the load parameter and the length of the product, the date of testing at a special load stand is also indicated.

Textile

The main material for the manufacture of slings is textiles, in particular, polyester tape. By color, you can roughly determine how many kilograms or tons one such element will withstand. Textiles are insensitive to corrosion from water, acid, oil products. These elements are easily brought under the load and hung on the hoist hook. A 30 mm wide textile element (one meter length) lifts a ton of cargo. There are also products with a length of 9 m.

Textile slings are also tape. Round-string products are made of high-strength polyester. Round-string products differ in maximum load capacity - up to 100 tons, while shaking fragile or dangerous cargo is excluded.

The STK marker is used to mark ring products, with the abbreviation STP - loop products. They are also made from completely synthetic, for example, nylon fabric. The latter include up to several layers of material. The label indicates the permissible load - from half a ton to 50 tons, as well as the version of the loop or ring component.

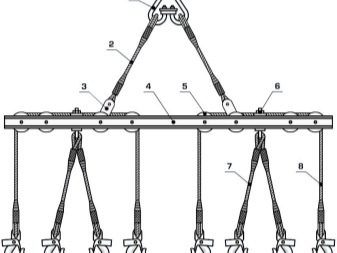

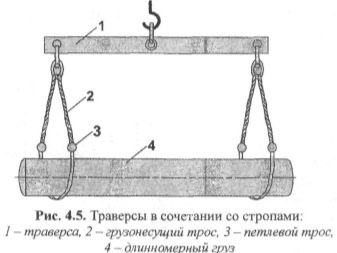

Traverses

The traverses are removable slings. They are used to move especially long loads, including those that move under conditions of a strictly limited lift height. Distinguish between lifting, assembly and magnetized traverses. Load traverses are attached with hooks, magnetic ones hold the load due to the attraction from a powerful magnet.

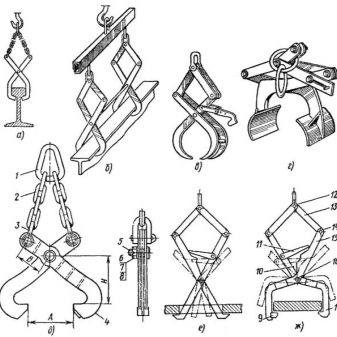

Grips

The grippers simplify the work of securing the sling elements on the movable load. The role of the gripper is a kind of assistant in the warehouse, through which tens of tons of similar and single-format stacks and blocks with goods pass monthly.

Gripping devices are made of medium and low alloy steel grades, due to which the working elements produced in this way acquire low weight and relative compactness.

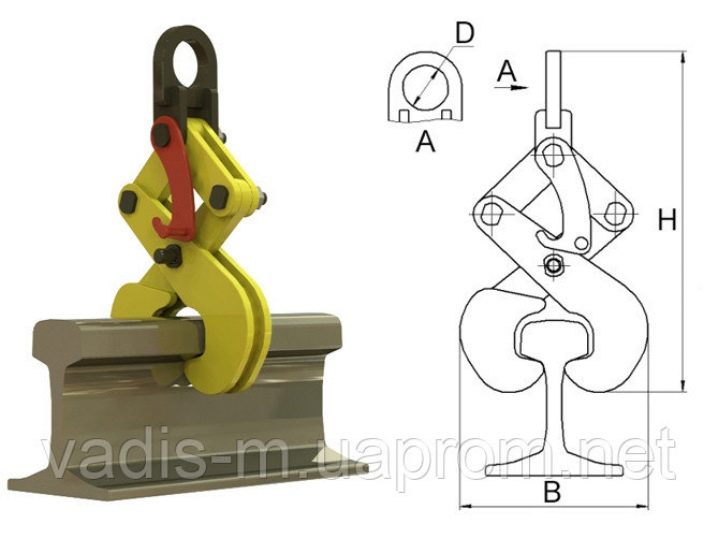

The pincer grip looks like a pair of scissors, whose ends cling to the entire load block or to its fragment. The eccentric product holds the load with the help of eccentrics - and is used when moving flat blocks and packages with goods. The clamp-type gripper is easy to use - it grips and holds the movable block. The fork element is placed under the bottom edge of the movable block. The rocker arm is used when moving blocks in which technological holes are provided. The wedge inserts a wedge into the hole of the movable block. The pin works in a similar way.

The use of a magnetic grip is possible when moving blocks, which include ferromagnets, while the power of the magnets is sufficient so that they do not move or fall. In the latter case, the current supply to the electromagnetic coil is influenced by the position of the switch, through which the supply voltage is supplied.

Components

Hooks, links, carbines, thimbles, load grips are used as accessories. The hooks have an impressive range of options in which they are executed, which allows you to effectively adapt to any need for moving lightweight loads. The thimbles are drop-shaped rings with hooks, the bent sides of which are encircled with a knotted rope.

The use of load grippers is justified in the case of moving rolls and sheets of blanks made of metals and their alloys, wood, plastic, composite. They have found application in the transport of pipes, pallets for bricks and other block building materials, including slabs. Load grippers evolved from another type of component - a hook. They represent its improved version, vaguely reminiscent of staples with pivot stops. Load grippers are completed with pivoting stops, eccentric components, forks, clamping devices, screw and pliers gripping tools. The availability of a specific type of such components depends on the specifics of the movement of cargo blocks and stacks at a particular facility.

Traverse devices provide for the use of beam elements connected to each other. They move containers, boxes, pipes, rolls, rails and sleepers, carry out car loading and unloading operations. Like load-handling devices, traverse are adapted to specific goals and objectives.

Inspection frequency

Preliminary inspection of products is carried out when purchasing such devices. It is important to exclude the presence of non-uniformity of weaving, breaks, frayed points and areas, grinding of ropes along rods and composite ropes... Rust on the steel cable is critical. A thin coating of rust on the hook is not a reason for the immediate exclusion of the purchase from the list of attributes required for loading or unloading.

Inspection of sling elements and additional devices is carried out on time specified in the data sheet for each type and variety of products... If the steel sling was used at a temperature of 1250 Celsius, then its permitted load will be reduced by 30%. Make sure that the loop or gripper does not slip along the load when moving it: vibrations of a raised package or stack may cause it to fall out or fall onto the area within which the load is being moved.

The comment was sent successfully.