Washing machine pressure switch: description, principle of operation and setting features

Every owner knows how to use a washing machine. But not everyone is aware of the structure design. In order to know how to fix this or that problem on your own, it is worth knowing the location of the parts and their functions, for example, a pressure switch. The normal functioning of the unit and the quality of the wash depend on this part.

Description

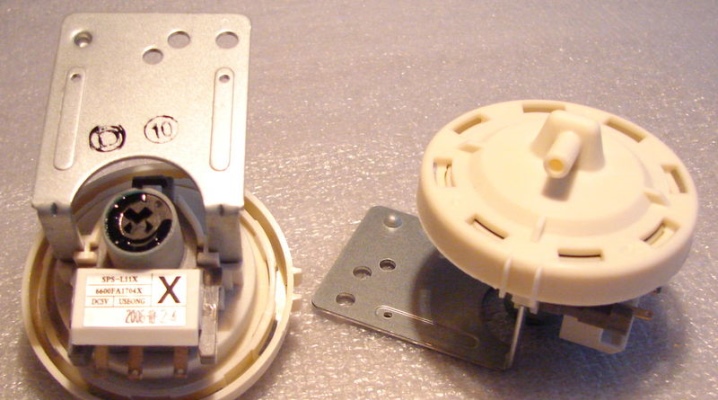

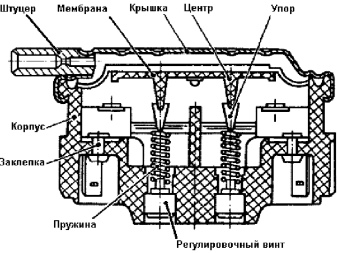

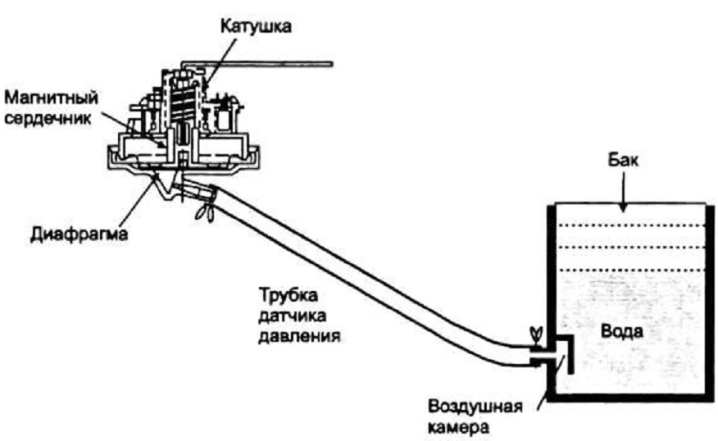

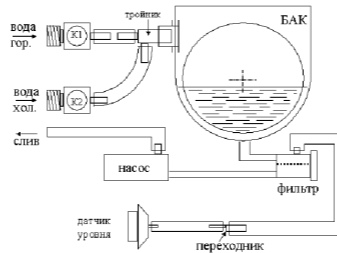

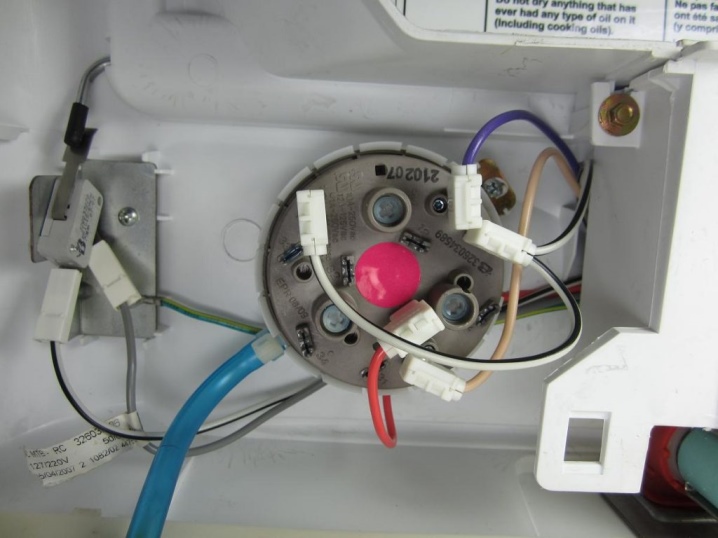

Washing machine pressure switch - This is a device that monitors the volume of water in the tank. The main task of the device is determination of the amount of liquid by the pressure of its column. The relay has the form of a disk, inside which there is an air chamber with wires and a tube. The complexity of the pressure switch design depends on the number of washing modes that the machine is characterized by.

The relay can be of simple or complex type. In addition, the electronic sensors are distinguished from each other by the stroke of its core and the membrane stiffness.

For this reason, a pressure switch from one unit will not necessarily function in another.... The sensor is made of high quality plastic, usually it looks like a round part. We need a mechanism for the correct functioning of the washing machine and high quality washing. This simple mechanical assembly consists of the following elements:

- frame;

- inductor;

- magnetic core;

- a diaphragm that changes shape under the influence of water pressure and displaces the core;

- contact group.

An electronic liquid level sensor can be found in the following parts of the unit.

- Under the top cover in washing machines of the classic type, where there is a front door for loading things.

- At the bottom under the tank in the technique, which is characterized by the vertical type of loading laundry.

- In the area of the rear of the case, slightly below the linen container, the pressure switch is located in those machines that have plastic drums.

Principle of operation

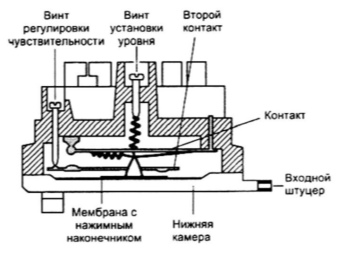

Each automatic unit for washing clothes has a water level control sensor. It is he who gives an electrical signal to the controller of the washing machine in the form of information about the presence or absence of liquid in the tank, which will be used for the procedure for cleaning things in one mode or another. When water enters the unit, the pressure in the pipe and the sensor chamber increases.

Due to the sensitivity of the membrane, the stem rises, after which it presses on the contact plate from the spring with a mechanism.

When the water in the tank reaches a certain level, it switches to the upper position, and the electric circuit of the lamellas is closed. If the water is drained, the pressure drops. In this case, the stem is lowered to the lower position, like the contact plate. As in the previous case, the electrical circuit is broken.

Malfunction symptoms

It is possible to determine the breakdown of the pressure switch of the washing machine using the error code that is displayed on the display. There are also other signs that the water level sensor is broken.

Cycle repetition

Due to the fact that the water level control mechanism is broken, it malfunctions or stops working. Wherein the control panel receives the wrong commands... In this case it is necessary to turn off the unit and replace the pressure switch.

Does not collect water

In some cases, situations arise when the machine is turned on does not collect water, but the procedure itself starts. It can happen when the contact is stuck in the "full" position or the automatic start of a dry wash.

Poor wash quality

Poor quality washing of dirty things occurs in the event that when there is not enough liquid in the tank, and the pressure switch is adjusted to low pressure... To remedy the situation, it is worth tightening the spring with the adjusting screw.

Remains water

Liquid may remain in the drum for some reason. One of them is a malfunction of the water level sensor and the elements that accompany it.

In some cases, at the end of the washing process, the dirty liquid is not completely drained, but at the same moment new water is taken.

The smell of burning

If there is no water in the washing machine or a burning smell appears, then this may indicate about a breakdown of the pressure switch or pump... In this case, the program starts the washing procedure, the heating element heats the liquid, and the lack of water in the tank triggers the heating device fuse.

Diagnostics and configuration

Each owner of a washing machine will find it useful to know how to check, set up, ring, adjust its pressure switch. Before you independently check the performance and adjust the sensor, it is worth clarifying whether the unit is under warranty. If this is the case, then with unauthorized intervention, you can forget about warranty service. The sequence of work consists in the following actions:

- removing the power cord from the outlet;

- dismantling the top panel by removing two small screws located on the back wall and sliding the panel back and forth;

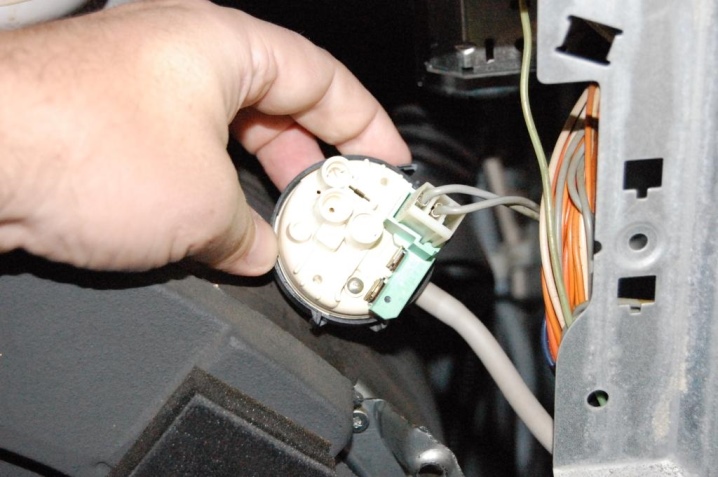

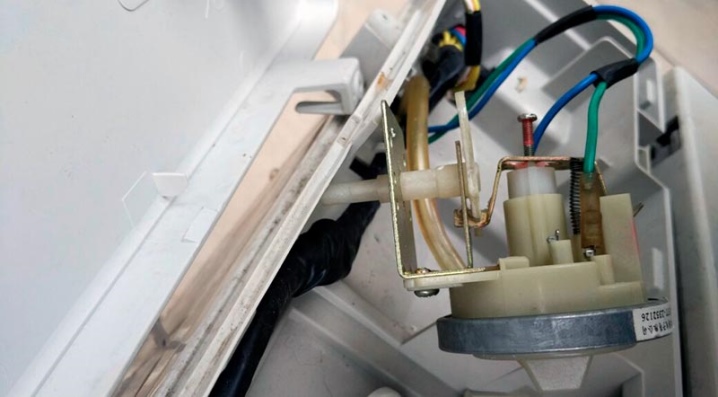

- detection of a pressure switch that is located on one of the body walls;

- removing the connector, loosening the screw, pulling the hanging sensor out of the machine;

- unscrewing the clamp and removing the device with pliers.

Before checking the adjustment of the device, it is worth assessing the performance of the pressure switch. For this purpose, it is worth preparing a piece of rubber tube, like on a relay.

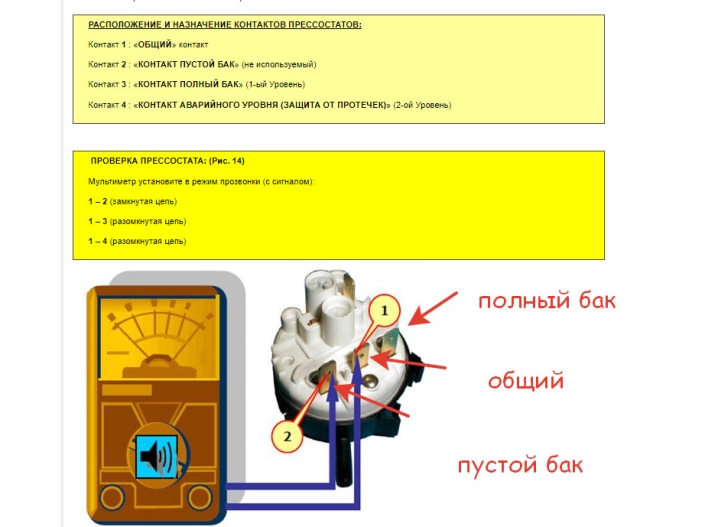

After the device is removed from the washing machine, it is connected to a small pipe. After that, you need to blow into it thereby to understand whether there is a click inside the sensor when the pressure changes. If there are no clicks, then the pressure switch is considered serviceable. To check the health of the water level sensor using a hardware method, namely a multimeter, you will need to perform the following measures:

- preparation of the device for determining the resistance;

- placing the probes on contacts that correspond to the electrical circuit of the pressure switch;

- the formation of pressure in the air tube until a certain contact of the relay is triggered.

If during the actuation of the contact there is no change in the resistance value, then the water level sensor should be changed. In the event that all of the above check showed that the mechanism is in good working order, then it will not be superfluous to conduct an additional check. The procedure is carried out by attaching the tube to the sensor and evaluating it for tightness.

It is possible to tune and adjust the mechanism at home when the level of liquid in the drum is not suitable for the user. The volume of liquid can be made more or less by adjusting the triggering force of the sensor. Before starting the adjustment procedure, you will need to disconnect the unit from the mains. To do this, remove the top cover, and also disconnect the connector from the relay.

The pressure switch has 3 adjusting screws, which can be visually identified by the presence of colored components in the slot.

The required screw that controls the primary force is usually located in the center of the relay housing. This part is usually made for a Phillips screwdriver, as well as an asterisk. It is worth adjusting the sensor when the tank is empty. The process is carried out in stages with the presence of intermediate, visual checks of the water level:

- by turning the key - assembly;

- connection - testing, etc.

It is recommended to turn the screw only half a turn at a time and no more. It is worth checking, changing, adjusting the pressure switch only if you have at least elementary basic knowledge of the theory. If there is no experience in this process, then it is better to entrust the procedure to a professional.

Repair features

The pressure switch works according to a certain scheme, which is nothing complicated. The owner of the washing machine can independently clean the pipe, remove the sensor or replace the device. A broken water level sensor can cause serious damage to the washing machine. If the user was unable to clean or repair the part in a timely manner, then the following problems may appear:

- water will cease to accumulate;

- the spinning of the washed laundry will deteriorate;

- over time, the heating element may burn out;

- the laundry will not be washed well;

- the tank will overflow with water.

In case of minor breakdowns of the pressure switch, you should not buy a new mechanism; setting up an old device can help with this situation. The sensor is replaced as follows.

- Removing the old relay by disconnecting the wiring, hoses. The procedure must be carried out with great care to avoid unwanted damage. After that, the fastening bolts are unscrewed, which fixed the body.

- Installing a new relay. The structure is bolted to the place where the old one was. After that, a hose is attached to it with a clamp and the electrical wiring is mounted.

The owner of the unit should remember that the sensor should be bought original or identical to the old device.

Before installing a new relay, it is worth checking its operability in advance. Immediately after repair work, the machine must be checked in several washing modes. In order to prevent damage to the pressure switch, experts recommend listening to the following tips.

- Do not use the washing machine at idle speed... Before washing, the drum is more than half full of liquid. If the device is empty, the sensor will soon break.

- Wash with extremely warm water. For a high-quality washing procedure, the temperature of the liquid should not be more than 45 degrees.

- Clean the drain on a regular basis. To drain the water from the tank without obstruction, the drain should be cleaned every 30 days.

Each washing machine is equipped with a pressure switch that controls the water level in the drum. In some cases, the relay may break down, after which it will need to be repaired or urgently replaced. If it is difficult for the owner to check or replace, then it is better to use the services of professionals. To increase the service life of household appliances, as well as their parts, it is recommended to use the machine strictly according to the instructions offered by the manufacturer.

How the pressure switch works, see below.

The comment was sent successfully.