All about glass-magnesium sheets

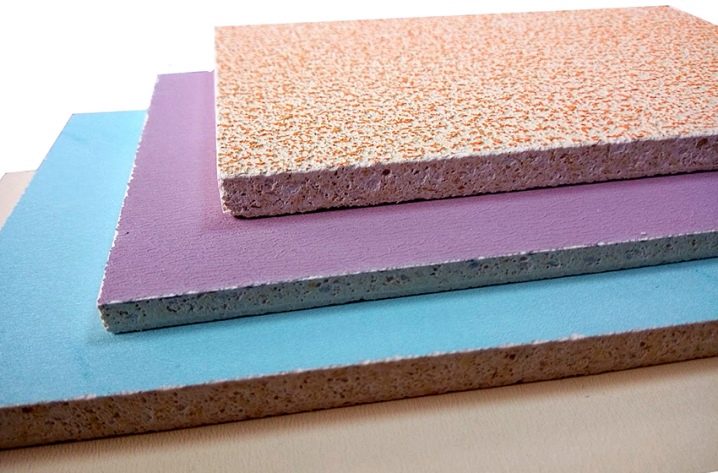

Magnesium glass sheet (LSU, novolist, construction sheet, magnesite, glass magnesite, magnesite plate, construction magnesia) are finishing blanks in which a magnesium-containing binder is used.

What it is?

The magnesite component of the SLM board includes sheet caustic magnesite material, magnesium chloride, expanded perlite and fiberglass. Additionally, LSU is supplied with synthetic material.

The advantage of the glass-magnesium sheet is fire resistance - the material practically does not burn. And also it poorly permeates moisture, no more than 5% moisture permeability. The salt component - magnesium chloride - has improved characteristics compared to simple cement mortar and gypsum mixtures. LSU is also called CML (Cement Magnesium Board). Additionally, wood shavings can be added to the LSU. Disadvantages of LSU - strength and ability to absorb moisture of workpieces are such that these qualities do not allow using LSU for external finishing of buildings.

LSU is mainly used for interior decoration, where there is no sharp change in temperature and humidity. Magnesite is not susceptible to mold and fungus formations.

The composition of LSU is represented by the following percentage of its components: magnesium oxide - 40%, magnesium chloride 35%, expanded perlite - 5%, wood chips - 15%, synthetics - up to 5%. The material does not emit magnesium chloride - like any salt, it contributes to a deterioration in the strength and other quality indicators of partitions and walls made of any material, be it brickwork, metal frame or vertical wooden floor.

Types and characteristics

The combination of different percentages divides LSU into classes such as "economy", "standard", "premium" and "ultra". The main parameter is the content of the magnesium astringent ingredient in terms of magnesium oxide. Technical characteristics in accordance with international and Russian GOSTs determine the variety of applications for LSU in repair and decoration, redevelopment of buildings and structures.

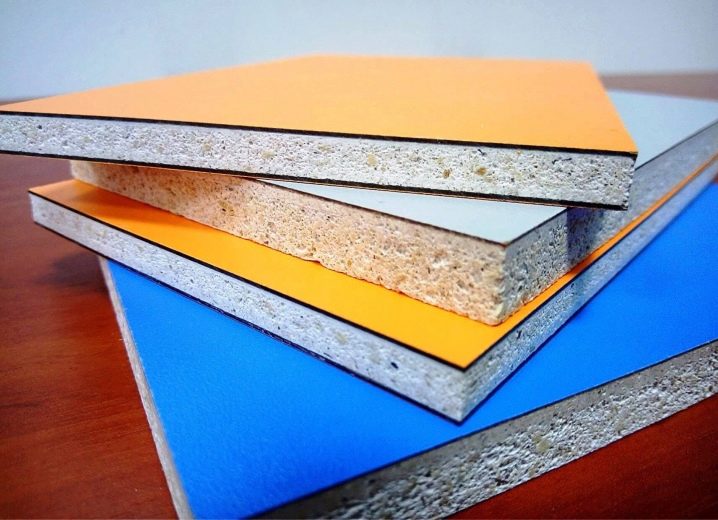

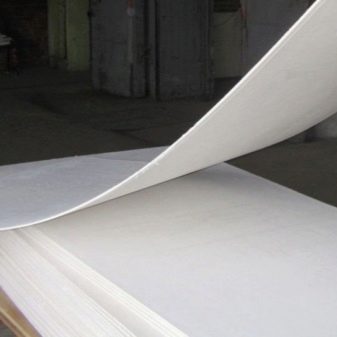

The sheet thickness is 4-14 mm. Typical values are 3, 6, 8, 10, 12 and 14 mm. It makes no sense to produce sheets smaller in thickness - they would easily crack and crumple. But even thicker LSU blanks are not produced: the moisture absorption capacity and sound insulation do not change with a further significant change in thickness. Blanks are produced mainly in 244x122 cm segments. The outer side of the sheet is smooth, there is no need to modify it. It is easy to stick vinyl or fiberglass on LSU. The reverse side (seamy side) is rough, but it is permissible to mount an LSU on any of these sides on a supporting base. Installation with the rough side outwards allows, for example, to putty a wall: the putty adheres well to the LSU surface due to its adhesion.

It is also permissible to apply gypsum plaster - a slowly hardening gypsum mixture, for example, the Habez brand.

The density of the sheet is 750-1750 kg / m3. Thermal conductivity - 0.21 W / m when heating / cooling one kelvin. The hardness is such that the workpiece can withstand pressure up to 50 megapascals without internal cracking throughout the entire volume of the sheet. Breakage force - no more than 20 MPa. The service life of LSU in severe winters is no more than 50 years, subject to the rules for the operation of the coating.Moisture self-deformation does not exceed 0.3%: a meter-long workpiece will not deviate from a perfectly flat analog by more than 3 mm, if one edge of the sheet is fixed. An eight-millimeter sheet withstands the flame for no more than 2 hours, however, high temperatures will gradually burn out fiberglass and synthetics, which will cause the product to begin to warp sharply. Sheets can be heated up to 1200 Celsius - the temperature in a fire in one room. Sound absorption of a 14 mm sheet does not exceed 46 decibels. The sheet is easily sawn and drilled, which does not cause additional difficulties with its installation.

LSU easily breaks and bends - like fiberglass, this material can be bent, having previously cut it in thickness, and also gently, along the same line, broken into two parts.

In terms of quality, the sheets differ in terms of density:

-

"Premium" and "ultra" version has a specific gravity of 1500-1750 kg / m3 and belongs to category A;

-

average quality of the "standard" type - 1250-1500 kg / m3 in terms of density, class B;

-

economical sheet - from 1000-1250 kg / m3, C-class.

Sheets of categories D, E, F, G are on sale, their density decreases and further - up to half a ton per cubic meter. Steklomagnesite is lighter than GCR by an average of 17.5%.

Manufacturers

LSU sheets are produced mainly by Chinese firms, but there are products made in Central Asia and Canada. Russian manufacturers are mainly represented by factories near Moscow, Kaluga, Tambov and Samara. The reserves of magnesium-containing ores (in particular, polymetals, from which it is possible to extract, extract magnesium) are deposits in China, Russia and Mongolia. In the Russian market, glass magnesite manufacturers are represented by the following list of suppliers.

-

Factory "SML-Don" produces glass magnesite according to Chinese and European technologies, but exclusively in Russia. The disadvantage is unstable high quality.

- Plant in Suifenhe (China) - supplies its products to Russia and the CIS. Product class - 1, uses sawn timber waste.

- "SML-Magelan" - Chinese products, imported to Russia. It is famous for its excess of magnesium oxide, whose deposits are vast in that country. Double-sided fiberglass mesh reinforcement.

- "SML-Gefest" - a plant near Moscow. Magnesium raw materials are mined in Western Siberia and partly in the Urals. In comparison with the Chinese, the Russian development is not fully formed as a product, the lack of LSU from this company is a mandatory quality check.

- "SML-Interpan" - a supplier from abroad, not a sheet manufacturer. The products are covered on both sides with plastic that does not support self-ignition.

- "SML-Uralchem" - Chelyabinsk plant, like its Russian competitors, has not yet fully adjusted the conveyor production of the product and quality indicators.

- "SML-Knauf" - a manufacturer producing glass-magnesite billets based on European technologies.

Quality control is carried out according to the following criteria: even and smooth edges without chipping, yellowish-beige tone. A white-grayish tone indicates a violation of the production technology (saving on magnesium). The surfaces should not be both rough or smooth at the same time. The presence of a glass covering with small (about 1 mm) squares is easy to notice - it must be present. A piece of glass magnesite immersed in water does not lose its shape in a few hours. If the water becomes cloudy, then this material will soon get wet, it cannot be purchased in significant quantities.

Applications

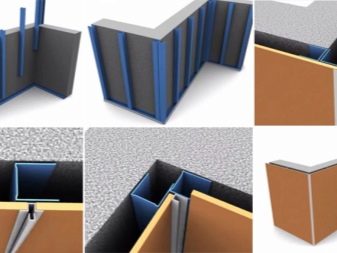

LSU blanks are used as a starting material for interior decoration of premises. LSU can easily replace drywall - however, it costs significantly less. They are used to organize partitions, for example, during the redevelopment of apartments and office floors. The main areas of use for glass-magnesium sheets are as follows:

-

wall cladding and arrangement of arched passages;

-

installation of suspended ceilings (false ceiling installed on the interfloor ceiling or on an old ordinary ceiling);

-

covering of mine passages of utilities (for example, ventilation systems, which include motorized hoods);

-

covering of slopes for windows and doors;

-

installation of permanent formwork;

-

use as a component in the organization of concrete structures;

-

installation of partitions instead of using gypsum board;

-

finishing of building facades with additional coatings on top of LSU;

-

arrangement of a mesh-free lathing under the roof (sheet profile);

-

creation of additional soundproofing internal coating in partitions;

-

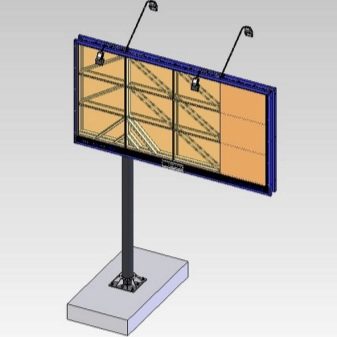

production of billboards;

-

arrangement of non-combustible passages near the exhaust pipes of boilers, fireplaces and stoves;

-

use as an internal water insulator in the bathroom or bath room of a country house located next to the living rooms.

Finally, LSU is sheathed with any materials, finished with decorative tiles or tiles, and decorated with stucco elements. A painted sheet is more difficult to distinguish in appearance from painted plywood than an unpainted one. Acrylic coated sheet on the smooth side, as well as laminated sheet, does not always need to be painted.

For the above purposes, glass-magnesium sheets are produced with more "round" dimensions - 125x250 cm. For filing ceilings, 6-8 mm glass-magnesium blanks are used, 12 mm - for dry screed and quick leveling of the floor.

The most common area of application of glass magnesite is wall panels and ceilings that do not affect the layout of the bearing walls of buildings.

Installation and operation

LSU blanks are finished by painting, installing plastic panels, applying waterproof varnishes. The smooth side will act as a finishing (finishing) finish. Due to the greater hardness compared to GSP, GVP, GKL - LSU, before fastening to self-tapping screws, they are drilled under the head of a self-tapping hardware, which allows it to be hidden in the thickness of the material, while filling the resulting grooves will lead to the fact that the screw heads will be hidden. If the density of the LSU blank does not turn out to be more than 1050 kg / m3, then a simplified installation is performed without drilling under the caps of self-tapping screws, as is the case with plasterboard sheets. As hardware, standard self-tapping screws are used - hardened or anodized - with a diameter of 4-5 mm (measured along the threaded edges).

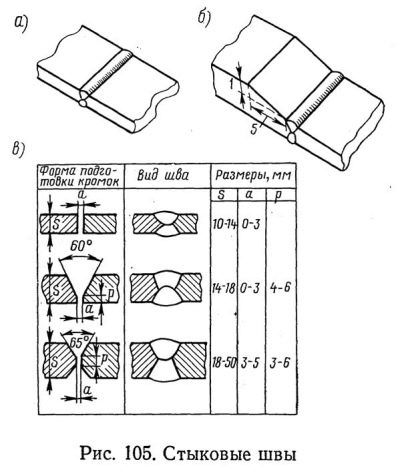

The joint seam of LSU blanks is filled by joining, or using acrylic or silicone-containing putty. The latter can be replaced with a simple rubber-like sealant, but the places where the sealant is inserted must be pasted over with masking tape from above. Installation of LSU on wooden floors is not accompanied by cement-containing putties or using gypsum mixtures: these materials, after drying, easily crack, which negates the use of these fillers, even when they are glued to the surface.

You cannot glue LSU blanks with adhesives containing polyurethane: the sheet takes all the moisture from the hardening glue, and it crumbles already during the drying process, without acquiring its inherent hardness, elasticity and plasticity.

Expensive gluing methods based on technologies such as PcA-Dm100 or PA-Dm100 are indispensable here. If we neglect the filling of the walls just finished with glass-magnesium sheets, then microscopic gaps may appear between the sheets, impairing moisture resistance and sound insulation.

The comment was sent successfully.