How to make a wardrobe with your own hands?

A wardrobe is a bulky and fundamental thing that is necessary in every home. Often purchased furniture is not suitable for the price, as the middlemen greatly inflate prices, sometimes they do not match in size or design. In this case, you usually have to look for a small company that is ready to fulfill a personal order. However, as practice shows, workshops ask for a lot of money. The most profitable solution in this situation is to make the cabinet yourself at home.

Views

Before starting work, you need to decide what kind of cabinet you need. Depending on the location, there are two main types:

- Built-in models, the main advantage of which is the presence of a floor, ceiling and some walls. This condition significantly reduces the cost of the project. Such options are convenient, since they can be adjusted to any existing niche: recesses in the walls, under-stair space. Oddly enough, this is also a disadvantage of built-in models, since they are built for a specific place and changes are no longer implied. Among other things, the curvature of the bearing surfaces greatly affects the quality of the cabinets, so they must be leveled before starting the project.

- Case free-standing wardrobes are a classic option. The models can be used in all types of premises. Parsing and transfer from place to place is possible. In addition, curved walls, floor or ceiling will not affect the installation. Among the shortcomings, one can note the high consumption of materials, compared to the built-in modifications, and the associated increased cost. However, with the correct selection of components, the cost can be reduced.

- Partially embedded models are a cross between the first two options.

Depending on the type of doors, cabinets are classified as follows:

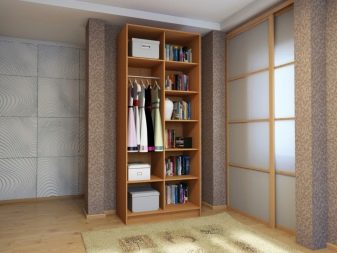

- Sliding wardrobe with sliding doors and a rigid frame. Two subspecies can be distinguished: with a roller mechanism for door movement and with a monorail. After appearing on the market, such options gained popularity with a variety of models, design, and internal content. In addition, the advantages are versatility, saving space in the room.

- Models with hinged doors. Long service life is the main plus of such options. As well as practicality and durability.

- Variants with lifting door leaves.

- Open, doorless cabinets.

Designers also divide wardrobes according to the type of equipment and style. The style is diverse: folklore, high-tech, baroque, empire, modern, rococo.

In terms of staffing, the following models can be distinguished:

- Typical options are typical for large industries, are made according to standard sizes, without frills. Practical and functional furniture. Most often used for offices.

- Serial production is a mass option. It represents the release of products in one line, with certain characteristics within the framework of one concept.

- Modular wardrobes have always been popular. Their advantages are mobility and functionality.Such structures can be divided into separate sections, easily dismantled, rearranged, combined with each other.

If we consider cabinets in shape, then the most common options are:

- Linear, in other words, straight.

- Corner (depending on the shape of the angle L or U-shaped).

- Round. Rounded side or bezels.

- Rectangular.

Depending on the number of doors, two-leaf, single-leaf, three-leaf or open doors are distinguished. Of course, combined options are also popular.

The most important characteristic of the cabinets is functional. Only after deciding on the purpose of the structure, all of the above classifications are taken into account. For the purpose of use, cabinets are:

- For clothes. This includes dressing rooms, wardrobes, which are characterized by hangers for dresses, suits, ties, trouser holders.

- For storing things. Here you can note bed linen cabinets, dressers.

- Book. They use various modifications from open to combined.

- Into the hallway. These models are characterized by shelves for shoes and hats, hangers-hooks, holders for umbrellas, a mirror, built-in sections for outerwear.

- For kitchen. Often, such cabinets are equipped with specific mesh or pull-out shelves for kitchen utensils and dishes, hooks for towels and other small items.

Materials (edit)

The most common cabinetry materials are as follows:

- Drywall. If a complex configuration is expected, then it is better to choose this option. Any shape can be bent from the gypsum board, since it is not afraid of deformation.

- MDF. From furniture boards that do not require cladding, rigid frames are made that do not require bends. The board is characterized by a high density, unlike chipboard, which makes it more durable. The fittings fit better inside, the probability of chipping when cutting the slabs is low. Conditional disadvantage - large mass. At a cost, the material is affordable, but more expensive than chipboard.

- Chipboard or chipboard. For cutting sheets, it is better to use the services of a workshop. At home, the quality of cuts can be low due to the lack of the necessary woodworking tools. From chipboard, you can perform various complex elements with the skill and the necessary machines. Chipboard is distinguished by a laminated layer that protects the sheet from external influences, and the user from formaldehyde. In addition, laminate flooring is good for decorative purposes as it mimics various coatings.

- Plywood. The material has a low cost. The service life of plywood products depends on the thickness of the sheet, the quality of gluing, and the indoor climate. In any case, for large structures, a large mass is unsuitable, since it will sag under its own weight.

- Solid boards. When choosing, it is better to use wood that is easy to process. Cabinets made of wood of such species as maple, ash, acacia, mountain ash, walnut, oak will outlive their creators many times over. It should be borne in mind that the cost of the project in this case increases significantly.

- Old boards. Recently, the vintage style has been gaining popularity. It allows you to give a second life to old things.

For example, having disassembled an old wardrobe, a table, a door made of boards, you can create an interior element such as a wardrobe, a curbstone, a chest of drawers with your own hands.

- Boxes. The fashionable hobby of making furniture from packaging cardboard is spread all over the world today. Usually one to three layers are used. Single-ply cardboard is usually used for interior walls and curved surfaces. To fill the volume - a material with a greater thickness. Boxed cabinets are the cheapest, but most short-lived option.

Materials for the execution of facades are of no small importance:

- The film is comfortable in every sense. For the facade, you can use the same materials as for the body, pasted over with a decorative coating.A wide range of films makes it possible to create vivid images, to design a wardrobe in the style of an existing interior. Moreover, it is easy to clean.

- Photo wallpaper. An excellent and inexpensive solution for facade decoration.

- A mirror is the most popular option, but rarely done when making cabinets yourself.

It must be remembered that mirrored surfaces are fragile, requiring certain tools to cut and fit the required dimensions.

- Lining. There are two types of material: wood and plastic. The facade, made of lining of various widths, is suitable for an eco-style interior, for country houses, balconies. Most often, wooden slats of 4 classes are produced. Panels of type "C" are subjected to the least degree of processing, therefore they can have knots and cracks. A, B and Extra are more attractive and have a low resin level.

How to get started?

The first step in making a cabinet yourself is design.

You need to approach it seriously, for this you need:

- Determine the location of the future location of the structure. The dimensions and the amount of required materials depend on this.

- It is necessary to decide what shape the cabinet is planned to be built: straight, corner, built-in, and so on.

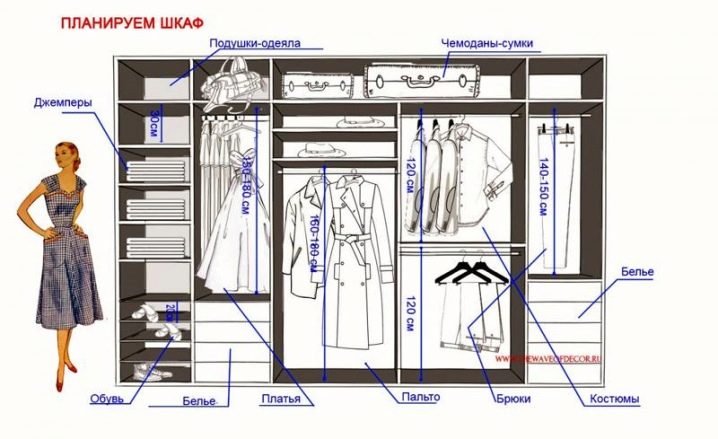

- Draw sketches of the exterior and interior. Determine in advance how many sections, boxes, shelves there will be. Fix the desired number of doors, sliding and hinged elements. Determine the order of the arrangement of hooks, hangers, holders. Even the need to install a decorative facade has to be decided at this stage.

- Choose a material, determine the color of the product, comparing all the parameters with the style of the interior. If necessary, decide what texture the facade should have. Designate a company that produces furniture fittings, based on the feedback of experts.

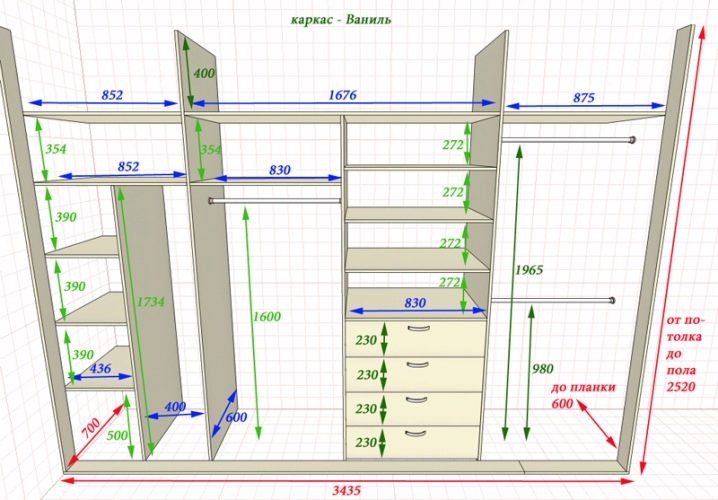

After that, various measurements are taken and calculations are made. It is necessary to understand that calculating the dimensions does not mean measuring the width and length of the cabinet. At the same time, it is necessary to measure the distance between the shelves, the width of the sections. All dimensions are transferred to the drawing for clarity.

When taking measurements, it must be borne in mind that the standard sash width should not exceed one meter. In addition, you should remember about the thickness of the sheet from which the body is made, therefore, 1-2 centimeters are added to the width of the sash. In the same way, the allowance for the height of the door leaves is calculated.

The scheme should be clear and take into account all the desired parameters. If it is difficult to complete such a drawing yourself, then you will have to contact the specialists.

Mount features

An important stage in the construction of a cabinet with your own hands is the selection of accessories. Today the furniture industry offers a huge number of fasteners and connecting elements. Their characteristics depend on the functionality of the cabinet and the operating conditions.

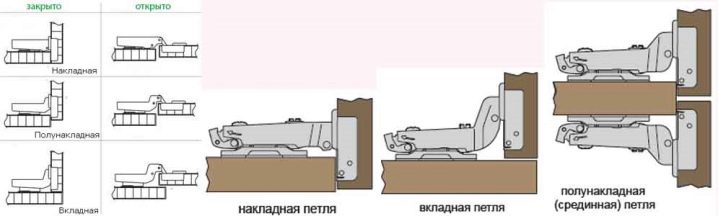

Often for wooden cabinets with swing doors, four-hinged door hinges are used, which are divided into several types:

- Overhead. The most common option for sashes.

- Half overlay hinges are advisable when one section is closed by two doors.

- Internal or hidden are installed on the inside of the door.

- Corner models are required for furniture located in corners, requiring the installation of sashes at an angle of 45 degrees.

- Inverted awnings allow the door to open 180 degrees.

- Piano mechanisms have a low degree of reliability, and therefore are rarely installed on cabinets.

- The mezzanine hinges have a spring in their mechanism.

Glass sashes can be fixed using the following elements:

- mounting strips;

- fastening loops;

- sealing rings;

- stubs.

For low canvases, two fasteners are sufficient; with an extension of up to 1.5 meters or more, the number of loops is increased.Optionally, you can install a closer to protect your fingers from injury and increase the durability of the mechanism.

There are several types of shock absorbers, different in technical parameters and installation method:

- The damper is the simplest and cheapest. There are many options on the market, the simplest of which is the self-adhesive model. It is a disc made of soft material with a thickness of 1.5 to 5 mm, a diameter of 7 to 10 mm, which is glued to the end of the case. For one sash, at least two pieces are needed.

- Hinge closer. It should be noted that such designs must be purchased immediately with a loop from one manufacturer. The model has the effect of smooth closing of the sash.

- Overhead and mortise shock absorbers, unlike those described above, do not depend on the type of hinges. The advantage of invoices is the ease of replacement, which does not happen often. However, when installing a closer of this type, additional space is required for the hole in the box from the end wall. The advantage of the mortise version is that the installation space is not required; on the other hand, it is more difficult to replace it.

For hinged doors, mechanisms are often installed that are designed to open up, down or in the form of an accordion.

The models are easy to install, their cost is low, and they are convenient during operation:

- Gas lifts and hoists combine the function of opening and closing up and down. The main selection criterion is the sash weight, since the device has varying degrees of force.

- Parallel, angle and accordion opening mechanisms. Advantage - great access to content, improved cabinet ergonomics. The disadvantage is the high cost.

Shelf mounts also have their own classification:

- Stationary ones are attached using several types of holders.

- Overhead, which are mounted to the wall, to the cabinet body or to the facade. The shelf in this case is superimposed on top. They represent different types of corners.

- Mortise built into the cabinet.

- Brackets are used for heavy loads.

- Retractable versions consist of rollers and guide rails along which they move. In addition, mechanisms are usually equipped with stops and seals.

- Rotating models. The main part is the axis of rotation, usually in the form of a pipe of the required height. Additional elements - fasteners for the upper and lower parts of the axle, flanges for mounting the shelf.

How to do it yourself: step by step instructions

Before you start working on a project, you need to prepare all the necessary materials, accessories and tools.

The following may be required:

- drill or hammer drill;

- level;

- ruler or measuring tape;

- pencil;

- hammer;

- glue;

- self-tapping screws, fixing accessories;

- screwdriver;

- hacksaw or circular saw (if you mean cutting out parts yourself);

- iron;

- construction knife.

The cabinet assembly scheme at home consists of several stages.

Parts preparation:

- Cabinet elements are cut from sheets of the selected material: cabinet walls, doors, shelves, drawer elements. Maximum precision is achieved with a circular saw. Sawing can also be done with a hacksaw, but in this case, without skill and experience, chips are possible.

Experts recommend using the services of a workshop, especially if it is necessary to cut it out of chipboard or MDF.

- Edge processing. For edging, PVC tapes are used, matching the color. Their cost is low, and it is very convenient to process the edges with it. Usually tape thickness varies from 0.4 to 2 mm. Usually, the thicker one is used for processing the apron of visible ribs, and the thinner one is used for those hidden from the eyes. The scheme of actions in this case is as follows.

- The iron is turned on three-quarters of its maximum power.

- The tape is applied to the end with an adhesive surface, ironed with an iron several times.

- Along the edge is carried out with a soft, dry napkin, pressing firmly.

- The remains of the tape are cut with a knife.

- Preparation of fittings. It is necessary to collect the right amount of fasteners, hinges, handles, hangers and other important little things.

Frame assembly:

- If the cabinet is built-in or will be located under the stairs, then most likely it will lack any frame elements: the lower or upper bar, sidewalls. In this case, the walls should be prepared for the installation of the structure, leveled, putty, painted or pasted over.

- If other options for cabinets are planned, then holes are drilled in the places of future fastenings.

- Connect the body parts together. First of all, the sidewalls are attached to the bottom, after which it is necessary to attach the upper part to them. For work, it is better to use the simplest fasteners - confirms.

- Verification of verticality using a level.

- If necessary, fix the back wall.

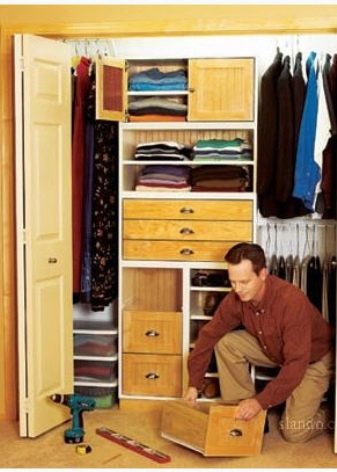

Installation of shelves and cabinets:

- To begin with, mark up the division of the internal space into sections. Next, note the location of the shelves and built-in cupboards.

- Sectional partitions are installed. Depending on the plan, they can be from the floor to the ceiling of the cabinet, or below. In the latter case, the presence of a horizontal partition is implied.

- On the side and sectional panels of the frame, fasteners for internal filling are installed. If stationary shelves are planned, then these can be ordinary corners. In the case of retractable shelves or drawers, guide chutes are mounted.

- Installation of other elements: hooks, holders, hanger bars.

Then the doors are fastened. In order to assemble the cabinet doors, it is necessary to adhere to certain algorithms for different door options.

Closet:

- Installation of the upper and lower guides, keeping track of their parallelism using a plumb bob.

- Installation of stoppers.

- Installation of roller elements on the door, if this type of mechanism is planned.

- The doors are inserted into the grooves, starting from the top, until they click.

- Check if the sash moves freely.

- Installation of additional fittings, if necessary.

Swing doors:

- Hinges of the selected type are installed on the doors.

- Shock absorbers are installed if necessary.

- Handles are screwed in.

- The verticality and closing mechanism are checked.

Folding and lifting doors:

- For hinged doors, gas lifts are most often installed. Purchased mechanisms are always equipped with instructions. Please read it carefully before installation. First of all, fasteners for gas lifts are installed on the side parts of the cabinet body.

- Such fasteners are installed on doors that will rise.

- Next, the doors are mounted using awnings or hinges from the side, which is in the future the axis of rotation.

- After that the elevators are fixed. To do this, their head must be put on the fasteners until it clicks on both sides.

- With the door closed, make the adjustment.

- Professionals focus on the fact that at least 2 mechanisms must be installed on one facade in order to exclude warping.

Then the cabinet is finished. At the end of the assembly, a complete polishing of the appearance is performed. All screws are sealed with decorative caps. Polishing with a soft cloth is necessary to clean the product from dust and drilling residues. Facades are designed depending on the designer's idea using mirrors and other decorative elements.

You can also see how to make a wardrobe with your own hands in the video below.

Organization of internal space

The functional structure of the interior filling of the cabinets consists of many elements that meet the requirements of the owner. A competent design should provide free access to any things in the closet, and prevent the formation of odors.

Drawers, sliding drawers, rotating shelves are not only convenient to use, but also ergonomic in nature. They allow you to efficiently use the interior space.For large wardrobes, lifting bars for hangers and trouser holders are often used, which can either rise or, if necessary, go into the depths of the closet. If the design is intended for a hallway, then it provides a box for storing shoes and shelves for hats.

Kitchen cabinets are filled with everything from swivel bar counters to pull-out chopping board. Due to the fact that it is necessary to store many different accessories in the kitchen, the functionality of the interior decoration of the cabinets is multifaceted and is determined only by the wishes of the owners.

How to place?

The wardrobe is the most bulky element of the interior in the room. There are options for their location that will allow you to "hide" and not clutter up the space.

In a niche

If the apartment has natural niches, then this will greatly facilitate the task. The wardrobe is simply built into them. Niches can be created artificially, which will allow not only installing structures for storing things in them, but also other interior elements: fireplace, TV.

Part of the room

If the area allows, then you can fence off a piece of the room and organize a wardrobe in it. At the same time, it is better to choose the darkest corner of the room so that the room remains bright.

Pantry

Private houses have different storage rooms. Sometimes they are found in city apartments. If the owner wishes, the closet can be perfectly hidden in the pantry. At the same time, efforts for its design are minimal, since the functions of the body are performed by the walls of the room. It is enough to organize the internal content.

In the room

The standard options for installing cabinets in a room are as follows:

- Wall to wall, floor to ceiling. A solid wall effect is created. Decorating facades with mirror surfaces will visually expand the space. When choosing doors the color of the walls, you can achieve the effect of "fading".

- Alcove. Cabinets are installed on both sides, forming a niche between themselves. The alcove formed in this way is filled with any interior elements: bed, dressing table, work area, TV.

- Openings. Door and window spacing can be used rationally with modular cabinets. Structures are mounted on both sides of the opening; mezzanines can be arranged above the opening. The element that connects the cabinets under the window is often designed in the form of a bench or sofa.

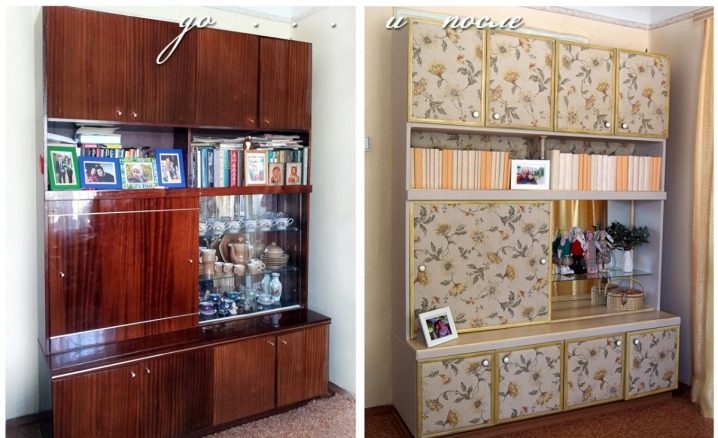

What can be done from an old cabinet?

If the old cabinet has lost its appearance, but the fasteners are intact and not loosened, the case also does not have significant drawbacks, in this case, you should pay attention to various techniques that allow you to redo or decorate outdated furniture.

There are many budget options to upgrade cabinets:

- Repaint yourself, for example using stencils.

- You can glue the doors with photo wallpaper or vinyl film.

- If the panels are glass or mirrored, then you can use the services of private workshops for matting or sandblasting.

- Decoupage using vintage paper or wallpaper.

- In the kitchen, you can use tiles for the decoration of facades.

If the fasteners still loosened and fell out, it is impossible to keep the cabinet in its original form. In this case, elements for another design can be cut out of its parts. Craftsmen create benches, shelves, poufs and other interior details.

Interior layout ideas

Large built-in wardrobes are popular. They are installed both in hallways and living rooms. They usually take up the entire space provided from floor to ceiling. Internal filling is organized depending on the wishes of the owner. Advantages - functionality, the ability to build in various elements for storing things, including vacuum cleaners, ironing boards, washing machines and dishwashers.Such structures can be installed in any places inaccessible for cabinet furniture, in attics, niches, corners.

Cabinet furniture also does not lose its position. This is evidenced by the wide range of cabinets offered on the market and the increasing demand for such options. The location of the cabinets in the interior entirely depends on the idea and imagination of the designer.

The comment was sent successfully.