All about heating elements for Bosch dishwashers

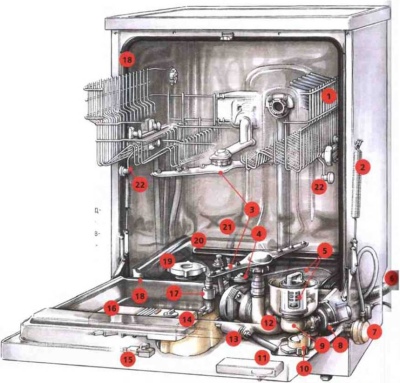

One of the essential components of any dishwasher is a heating element or a tubular electric heater. Its main function is to heat the water to the required temperature, which was set by the user.

But, like any technical device, the heating element can break and fail. Let's try to figure out how the heating element for the Bosch dishwasher works. In addition, we will analyze how to choose a new heater for such a dishwasher, why it can break down, and how to replace it with your own hands.

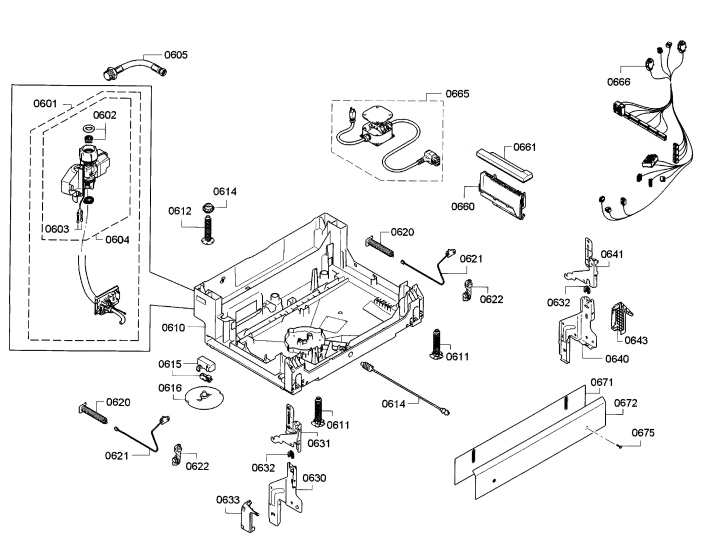

Device

As already mentioned, a heating element is an electrical appliance, the main purpose of which is to heat a liquid with a built-in spiral, which is made of a special material. The conductive part is located in the tube, which is airtight. By the way, it is isolated from the dishwasher body. The heater is usually housed in a special water jacket. And in order for the liquid to circulate, a special vane-type electric pump is used. The joints of the parts are sealed with a rubber gasket, which protects the contact parts from water ingress.

When an electric current flows in a spiral, heat is generated. The measurement sensors are responsible for regulating the operation of the heater. The sensor monitors the programmed temperature, and when the set level is reached, it turns off. When the water cools down and its temperature drops below a certain level, heating is carried out again. It should be added that Bosch tubular heaters installed in dishwashers manufactured after 2010 are additionally equipped with a pump. Such models with a pump are distinguished by a more intensive circulation of water, which significantly speeds up heat exchange.

Dry knots can be found in a number of models from the mentioned manufacturer. Their characteristic feature is that the heating tube will be mounted here in a special case. And the space between the walls is filled with a special compound that is resistant to high temperatures. Its task is to provide additional insulation from the effects of liquid on various electrical parts.

Causes of breakdowns

Malfunctions of heating elements and their breakdowns can occur for various reasons. Coiled filament burnout and lead-out shorts are commonly cited by users as the most common faults. Here it is necessary to understand that burnout occurs as a result of the fact that the refractory element located in a hermetically sealed heater becomes thinner as it is used.

You can often find that the flow heater installed in the dishwasher simply burned out. There may be several reasons for this phenomenon.

-

There is a leak somewhere in the tubular electric heater.

-

The filter is too dirty, due to which it cannot perform its function normally.

-

The dishwasher is not being used properly, or it happens with some serious malfunction.

-

Deterioration or large accumulation of scale directly on the heating element. If the thickness of the scale on the thermal electric heater is more than 2-3 millimeters, then the part will definitely break, and quite quickly.

-

A breakdown can occur due to a serious voltage surge in the electrical network. If this is a common occurrence in your area, then you should get a device such as a stabilizer.

If the breakdown is serious, then you can check the condition of the heating element, but it is almost guaranteed that it will need to be replaced. Before that, you must first purchase it after careful selection. And in order to choose it correctly, it is necessary to take into account a number of specific features.

How to choose a new heating element?

Before ordering and buying a new heating element, you need to know about the model that is installed in the dishwasher, everything, down to the serial number. It can be found on the dishwasher's label.

In addition, you should know the main technical characteristics of the device:

-

voltage and power;

-

dimensions;

-

correspondence to the connector for connection;

-

general purpose.

In addition, it is required to pay attention to the tightness at the ends of the outlet on the model. And also you should pay attention to the design features. Electric thermal heaters used in Bosch brand dishwashers can be:

-

wet or submerged;

-

dry.

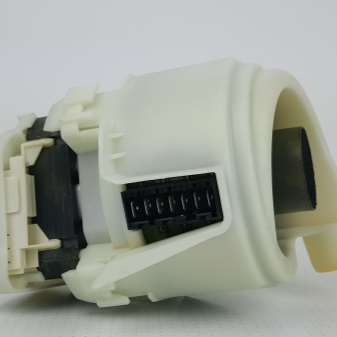

The first category of devices differs in that they come into contact with the working liquid medium and heat it up. And the second category of models is in a special flask made of soapite. This material belongs to the composite category.

Dry type heaters are more in demand due to their higher efficiency. This is achieved due to the fact that the part does not directly contact the liquid. This also makes it possible to increase the durability of the part.

The presence of a wide flask in a dry heater allows you to heat the water as quickly as possible, protects against the formation of scale and the formation of the so-called dry plug. And, if necessary, it is somewhat easier to remove such a part.

In different models of Bosch dishwashers, sensors for turbidity of a liquid, water flow distribution, as well as an electric relay, which is switched by a membrane, which is moved by a water pressure, can be installed.

Note that for Bosch models you can find heating elements, complete with which there is also a pump. It will be one piece that cannot be disassembled. But its price will be significantly higher than that of conventional thermal electric heaters for such devices.

How to replace?

Now let's try to figure out how to repair the dishwasher by replacing the heating element. First, you need to disconnect the commutation hose that is connected to the water supply. After that, you need to disconnect the waste fluid drain hose, which is connected to the sewer.

You should also disconnect the dishwasher from the power supply, after which the case is disassembled, and the necessary element is replaced.

To perform work, you will need to have on hand:

-

screwdriwer set;

-

pliers;

-

tester;

-

spanners.

The very process of replacing the heating element will be carried out in a certain order.

-

We open the front door of the device, remove the trays from the inside where the dishes are placed.

-

We dismantle the liquid sprinklers made of plastic, and also remove the filtration unit from its nest, which is located at the bottom of the chamber.

-

If the dishwasher is an integral part of the kitchen wall, then you should unscrew the fastening screws on the sides and in the body lid.

-

Pull up the lower spray arm, which is usually held in place by a spring-loaded retainer.

-

Remove the plastic pipe connected to the heater.

-

We take out the dishwasher to remove the covers that are located on the sides. If the equipment is built-in, then it will be enough to dismantle the noise insulation panels and remove the plastic shields.

-

We put the equipment on the back wall, before placing a damping material.

-

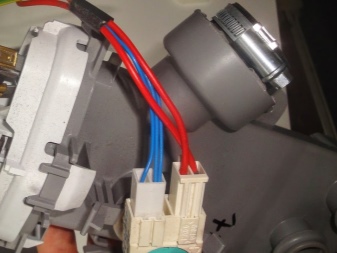

We dismantle the lower area of the body with adjustable supports, after which we disconnect the water hose from the heating unit. Take into account that water will flow out of the hose. If the hose is stuck, then you need to use pliers. Under no circumstances should force be applied due to the risk of breakage of the nozzles.

-

We disconnect the commutation cables and unscrew the fasteners that fix the heater case. And you should also unfasten or snack on the plastic fasteners that hold the electrical wires. Now we remove the burnt part.

-

We carry out the installation of a new thermal electric heater, and assemble the equipment in the reverse order.

-

We make equipment testing.

And you should also know that before replacing the heating element in the dishwasher models of the brand in question, it is required to measure the resistance of the part in question, which will be installed instead of the broken one.

The manufacturer unifies the design of the dishwashers, which is why the winding resistance may be lower than necessary. For example, a technique with a power of 2800 watts at a voltage of 230 volts should have a resistance indicator of 25 ohms, and you can see only 18 ohms on a multimeter. Lowering this indicator allows you to accelerate the heating of the liquid, but at the expense of reducing the reliability and durability of the equipment.

To increase the resistance, the process bridge can be removed, which separates part of the heating coil. To do this, you need to dismantle the pump housing that is installed on the heater. The disadvantage of this step will be the loss of the warranty for the part and an increase in the cycle time due to the fact that the intensity of water heating will drop.

The comment was sent successfully.