Felt Polishing Wheels

The felt polishing wheel is a suitable tool for treating various surfaces from rust or paint residues, giving shine and removing chipping, scratches and other minor defects from an object. You can purchase a specialized or universal disc from the felt. We will understand all the features of this device in our article.

Varieties

Felt polishing wheel applied:

- metal (ferrous, non-ferrous, precious) or various alloys;

- stone (artificial, natural or precious);

- glass and crystal.

They also use felt or felt for natural wood furniture, amber products, plastic materials and rubber.

The polishing disc is divided into several types, the division is based on the percentage of fiber.

- Fine-haired... It is used for polishing car bodies, non-ferrous metal surfaces, and aluminum objects.

- Semi-coarse... This disc is used to grind medical instruments such as a surgical scalpel. Also, such a circle is in demand when polishing parts for measuring instruments and devices.

- Coarse... The disc is necessary for polishing metal surfaces, giving the desired parameters of alignment and gloss.

Most often, a Velcro tool is used, but there are also varieties on the spindle. It is more convenient to use a velcro disc, since it is easier and more convenient to replace the disc.

Materials (edit)

The best discs are obtained from a very dense felt, they are wear-resistant, while the more elastic ones lose their properties much faster. Polishing wheels are made from raw wool by pressing. The main component is natural sheep hair of various degrees of preparation (semi-coarse, regenerated, fur), as well as wool fleece and cow wool.

The advantages of pressed felt discs are:

- increased strength;

- small mass of the circle;

- plastic;

- the ability to hold polishing pastes on its plane.

There are three main percentages of natural felt used in polishing wheels, which correspond to GOST 756-89... The fiber used is categorized as: fluff, guard hair, transitional hair, and dead hair. The most elastic composition is obtained with downy hair, and the toughest - from the dead. The main indicators of the compositions look like this.

- Fine-haired felt disc... The down is 90%, the transitional hair is 5% and the guard hair is 5%. The most elastic material is obtained.

- Semi-coarse felt disc. Fluff is 30%, transitional hair is 30%, guard hair is 35% and dead hair is 5%.

- Coarse felt disc. Consists exclusively of 100% dead hair.

Dimensions and weight

Polishing wheels are made from even flat layers of felt mat of small thickness. The standard industrial parameters of the discs are as follows: the common diameter is either 125 or 150 mm, the thickness is from 20 to 50 mm. Specialized discs can be 250 mm or larger. The weight of the circles is small and depends on the parameters mentioned above, usually from 50 to 200 grams approximately. The marking of such circles can often be a combination of three parameters: 150x20x32, 50x25x6 mm, where 150 and 50 mm are the outer diameter, 20 and 25 mm are the thickness, 32 and 6 mm are the inner diameter.

In a home workshop, you can use unnecessary felt boots or any felt thing cut into thin layers to create a polishing felt disc. These layers are glued together, and the glue is applied to the entire work surface, with the exception of a narrow strip at the outer edge. This is done to avoid the ingress of abrasive materials when using the wheel on the working surface. After gluing, the workpiece is dried under the pressure of the press.

A hole for the fit is cut in the dried workpiece of the circle with a metal pipe of the required diameter with sharp edges. For the required rigidity, two washers are fixed in the bore hole, and their diameter should be one third of the outer diameter of the circle. For quick replacement, the polishing disc is attached to a small threaded rod.

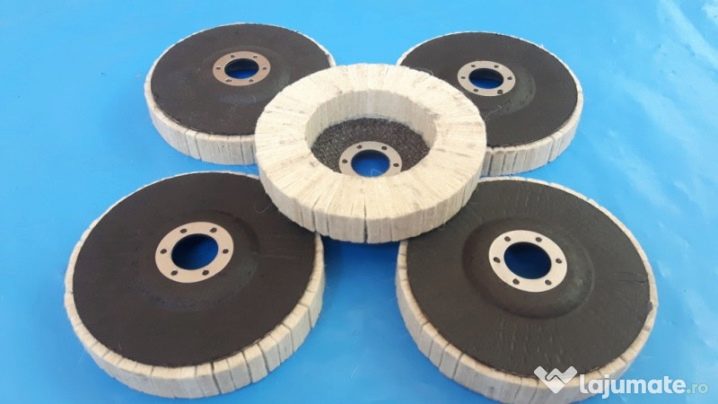

Felt polishing discs are divided into two types in terms of shape.

- Petal... High yield and high cost.

- Surface grinding... They look like a rubber disc, have a special coating for surface treatment.

Manufacturers

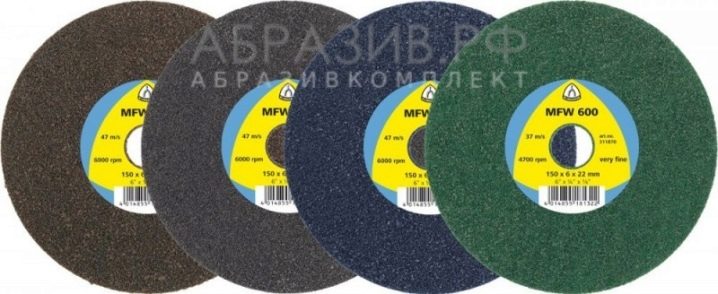

Klingspor

A German manufacturing company that has earned the trust of Russian buyers. The tools produced by the company have a long operational life and budget cost, all products are of high quality.

Orientcraft

A large company from China manufactures low-cost, high-quality abrasive materials. The goods produced are exported to 30 countries. Approximately 70% of all exports go to European territory and Japan. An international Chinese company produces abrasive materials at affordable prices.

Farecla

The company from the UK, manufactures products for the decoration and painting of cars... The brand's products are selling well on the global market, in more than a hundred countries around the world. Huge selection of surface treatments: abrasives, solvents, paint brushes and electrical equipment.

Matrix

For home use, the company produces budget and very high quality polishing wheels. In the Russian market, the company has proven itself very well.

How to use?

Polishing work on metal surfaces involves the use of Goi paste in any form, but it is advisable to choose thick gel-like varieties... You need to apply Goi paste on the polishing wheel, a small amount is enough and start working. Thus, it is possible to clean any metal thing from corrosion or heavy contamination.

Most often, a felt wheel is used as an attachment for a drill or screwdriver.

The polishing drill can break quickly if used continuously. This happens for the reason that the drill is designed for a straightforward load, and when polishing different surfaces with a tool, they work, often putting it on its side. For this reason, the bushings usually break.

It is possible to use a drill in polishing work, but it is undesirable.

For a grinder, a felt wheel is more suitable, but do not be mistaken - the revolutions in an angle grinder are much higher than in a polishing one. For finishing work with a grinder, you must use a tool with the regulation of this parameter. For the correct operation of the felt wheel in glossing, it is necessary to use the instructions of professionals, where it is announced how to work correctly with a polisher, how many revolutions you need to set. To prevent overheating of the paint and erasure of the paintwork, grinding should be carried out at an indicator not higher than 1000-1200. Household drills may not have this speed.

If the rules for polishing are not followed, a number of problems arise:

- overheating of paint - from overheating, the polishing mixture adheres to the polished surface;

- deterioration in quality painting the coating, changing the texture;

- as a result of careless actions it is possible destruction of the protective layer;

- overestimated number of revolutions can completely remove paintwork to bare metal;

- non-observance of the rules for working with polishing may result in to the need for a new painting.

For emery, a felt wheel is also great. On the free sale you can buy special discs for a grinding machine, the bore of which has the most popular diameter - 32 mm. Such a circle is made of high density felt mat, it does not crumble, and with the correct working process, the service life is long. As for the latter, to extend the latter, it is not worth grinding the edges and working only on the surface.

Many people mistakenly believe that polishing with a felt wheel is a simple and safe process. In fact, this is not entirely true, because if the grinding process is performed incorrectly, the coating can be damaged. It is also necessary to take into account the quality of the purchased felt circle and select the required diameter.

If you follow these simple recommendations, then perhaps you will like to carry out polishing work.

The comment was sent successfully.