How to make a door to the bathhouse with your own hands?

The bathhouse has many useful properties that have a beneficial effect on health, so everyone who has a suburban area has thought about building his own bath at least once. This can be done not only using the services of builders and experienced craftsmen, but also with your own hands.

What should be a homemade product

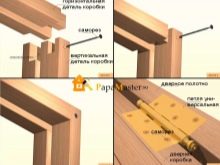

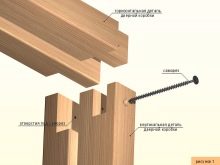

The entrance door to a block bath should be single-leaf, narrow and low, it should not take up much space. The entrance doors to the bath, as a rule, have metal hinges located inside the room itself, and open outward. In addition, a small threshold is required, corresponding to the upper edge of the floor surface. The role of the required hood is played by the gap that forms between the threshold and the door.

It is advisable to install a bath door made of wood., since it is characterized by low thermal conductivity, as a result of which heat loss and power consumption are significantly reduced. It should be upholstered with heat-insulating material and be sure to treat it with leatherette. In addition, the entrance door to the bath must comply with such requirements as heat resistance, resistance to decay and mold formation, durability, environmental friendliness and, of course, high strength and good quality.

When installing the door to the dressing room, preference should be given to such a design in which the door from the steam room will open into the dressing room itself, and not vice versa, which will help to avoid the accumulation of moisture. The door should be chosen with a focus on resistance to high temperatures and characteristic heat resistance, which is one of the most important aspects. It is better to upholster it with insulation that is not afraid of steam in order to ensure the greatest durability.

Materials (edit)

Bath doors can be made of various materials.

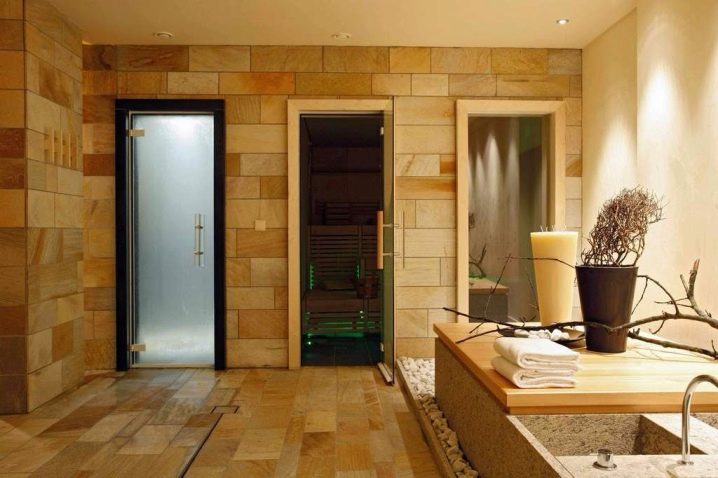

Glass

Glass doors are popular in Turkish and other saunas for a reason. This material easily withstands high temperatures, is not afraid of humidity and does not imply whimsical panel maintenance. The glass used to make the door must be heat-resistant, impact-resistant and tempered. Glass doors are always supplied with silicone seals, which are necessary to ensure tightness when closed.

In addition to the fact that the glass bath door looks completely beautiful and is distinguished by its inherent attractiveness, it has an almost unlimited life, which is not a characteristic feature of wooden doors. The process of decay, deformation and release of harmful substances is not inherent in glass, however, it is very difficult and prohibitively expensive to independently install a glass door so that it meets safety standards.

Wood

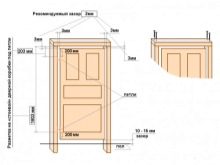

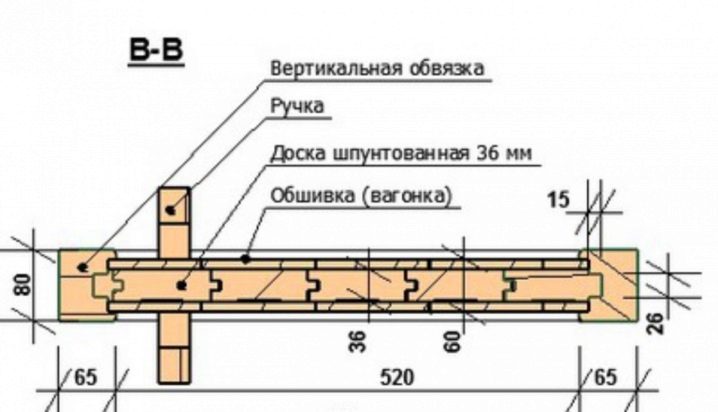

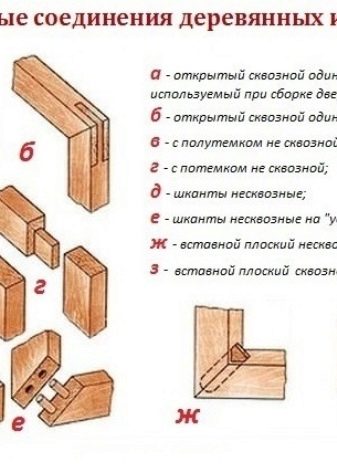

Another equally popular material used for the manufacture of sauna doors and considered traditional and most functional is wood. It is well able to withstand any changes in temperature and humidity. The most reliable option when choosing a material for a door to a bathhouse with your own hands and preferred by experienced craftsmen is tightly knit boards made of aspen and linden. Doors, which are particularly massive, are usually made of wide and grooved boards.

For doors that are installed at the entrance to the steam room, transverse beams or, as they are often called, dowels, which are necessary to securely fasten the boards and prevent their deformation, are considered mandatory elements. It is advised to choose beams and forcing not from conifers, but from deciduous ones, since otherwise resin will be released when heated. When decorating a door with clapboard, pay attention not only to its quite acceptable cost, the relative lightness of the cladding, but also to its low moisture resistance. As a consequence, periodic treatment with protective varnish coatings is inevitable.

Necessary materials

In order to build a dream bath with your own hands, the first thing you need is tools, without which no business can do during construction:

- A stove hammer used to cut bricks and hammer in nails.

- Kirochka. The difference between a pick and an oven hammer is that both ends are sharply sharpened and serve to cut bricks.

- Trowels are blades with webs of different shapes, needed in order to collect and lay the solution, giving it the thickest consistency and, if required, homogeneity.

- Scrub brush. Used for grouting oven masonry, as well as mopping it and giving the surface a smoother appearance.

- Plumb line, which is a weight close to a cylinder. This tool is used to check how vertical the oven masonry is. In addition, the plumb bob is used to carry out dimensional verification by means of a special cord.

- Level. This tool looks like a wooden, metal or steel bar. The levels should be handled with extreme caution, since the existing glass tubes, that is, the sighting devices that make up an integral part of the entire structure, can be easily broken.

- A wooden paddle is used to stir solutions.

- The wooden shovel is used primarily to prepare the clay mortar.

- A steel shovel is mostly needed when cleaning debris and mixing solutions.

- Cycle. This tool is made of steel, one of the sides of the plate of which is well sharpened, after which this sharp end is wrapped in a durable material like rubber and leather in order not to get hurt.

- The stukalese is a round steel cut. It is convenient for them to strike with a knife instead of a hammer, in order to exclude the possibility of a miss.

- The concrete mixer will be an excellent assistant for carrying out foundation work.

- The chainsaw is a must and irreplaceable when working with logs.

- A screwdriver is an equally necessary tool in any business related to construction.

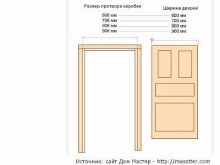

Determine the dimensions

Determining the dimensions is one of the first and most important steps in building a bath. It should be noted that there are no universal sizes. It all depends only on your imagination and even more on your preferences. This also includes the number of rooms that seems to you the most optimal, since the bathhouse can be designed not only for a family, but also for a whole large company or for one single person.

The dressing room does not need to allocate a large space for it, since the stay in this room is not long, but the dressing room is the largest room in the entire bath, which often takes up almost half, or maybe more. The washing room most often occupies about one third of the total area, but do not forget that the dimensions of the premises depend to a greater extent on the total area of the entire bath.

There will be enough 2 * 2 meters for the steam room, so that 3 or even 4 people can easily fit in it.

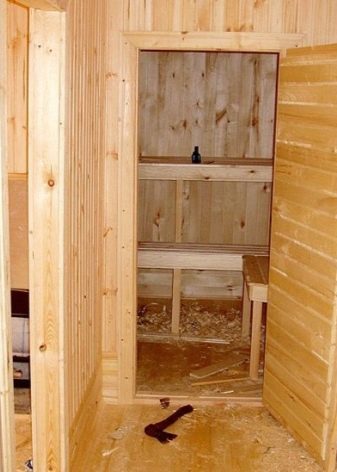

Step by step manufacturing

The plan, according to which the bath is being built, is as follows.

- Any construction, as you know, originates from the construction of the foundation, which is the foundation.When the required dimensions of the bath have already been calculated, trenches are made and filled with everything necessary, after which it is already possible to knead the solution.

- The next and equally important stage is the construction of walls, the material for which is most often wood. The logs are stacked on top of each other exactly until the intended height of the structure is reached.

- Next, you can make a roof. This is a complex process that begins with the installation of the ceiling beams, followed by the installation of the roof itself, which includes sheathing, in which you need to fasten the boards, boardwalk, vapor barrier, insulation and finally waterproofing.

- After that, you can proceed with the installation of the floor and the heating stove. The installation of the floor, as well as the manufacture of the roof, is carried out on beams. At the end of the construction of the floor, it's time to move on to the installation of the stove. It is best to pre-determine the location for the installation of the boiler. In order to simplify temperature control, you should opt for the adjacent wall between the dressing room and the steam room.

How to install a glass product?

Installing a glass door in a bath is not a laborious process that requires a lot of knowledge required for that. It is necessary to lift the canvas and insert it, cut it into the doorway, securing it with wedges, fasten the screws of the upper part of the door frame from the hinge side. To prevent the screws from falling apart, you can collect them with a magnet. This will put all the details in one place.

When the door leaf is fixed in the opening, the distance between the wall and the door itself should be filled with foam, which has the property of moisture resistance. Tightly compact the pieces, while not allowing them to protrude outward. However, if this cannot be avoided, simply cut off the excess.

When installing a glass door, you need to make the bottom clearance up to 5 mm. A special silicone seal is an integral part of the door installation if you count on good heat retention.

In order to avoid the risk of mechanical damage to the edges of the solid glass of the bath door, remember about the wooden strips that need to be placed to fix the glass on both sides.

How to install a glass door, see the following video:

Thermal insulation of a bath from the cold

Insulating from the inside is a mandatory aspect when building a bath. This step will help reduce heating costs, maintain the desired temperature and speed up the heating of the room.

Thermal insulation materials are usually divided into two types:

- organic origin;

- inorganic origin.

A very important factor is considered not only the heat-insulating and moisture-resistant characteristics of the insulating material, but also its environmental friendliness. In order to prevent heat from escaping to the outside, the plinth is often sheathed with foam plates, fastened with glue. To insulate the walls of the bath, a crate of bars is used. If necessary, the insulation is sometimes put not in one layer, but in several at once. Clapboard sheathing is the last stage in which a small gap is left to prevent the material from rotting.

Ceiling insulation should not be ignored, otherwise 15% of all heat will be lost. The ceiling in the bath is insulated with foam boards, which significantly reduces heat loss. After the seams are sealed with special foam and vapor barrier materials have been used, you can proceed to the boarding.

Finishing options

When arranging a bath, you should not forget about its decoration and sheathe it.

The material on which your choice will fall may be different and meet a number of necessary requirements:

- Hygiene;

- Strength;

- Durability;

- Resistance to toxic emissions at high temperatures;

- Good external characteristics.

Many people prefer lining, as it has many positive qualities, for example, medicinal properties and complete safety of the material. Also, plywood is often used to decorate the bath.In addition to its undeniable attractiveness, this material has a number of advantages. It is very durable, stronger than drywall, has a low cost and does not hit the wallet, and also has sound insulation properties and is lightweight. One of the parameters of a plywood sheet is the grade, which is divided into 4 types. If the interior decoration with plywood is done correctly, then it will not cause any trouble for a very long time.

What and how to paint correctly?

When choosing a paint, you should be aware of whether the selected product meets certain evaluation criteria. The paint should protect the wood surface from aggressive mechanical influences, while maintaining its integrity, withstand the prevailing high temperatures and, in addition, ensure the aesthetic appearance of the surfaces. Also, when choosing a paint, you should definitely take into account the type of wood used.

- Before you start painting, prepare the area for work by preparing the necessary brushes, ladders, stools and other necessary things.

- Sand the wood just enough to smooth the surface with your palm so that a splinter won't hurt your hand.

- Apply a thin coat of the paint of your choice and wait until completely dry, re-sand the surface with sandpaper.

- You can now coat the wall with a second finishing coat, preferably using a spray gun.

Instead of paint, you can also use a special varnish, which has its own distinctive features and advantages. For lovers of wood texture, this option will be preferable, since the lacquer surface is characterized by the property of emphasizing it. In addition, if you use varnish to cover the walls, then the possibility of mold, fungus and bacteria will be significantly reduced. An additional convenience is the fact that it can be applied in a new layer without preliminary cleaning from the previous one.

Advice

Experts have prepared several useful recommendations.

- For the greatest comfort in the bath room, you should pay attention to some of the recommendations of experienced masters. For example, it is better to install a bathhouse on the south side, since in winter, when you sometimes want to take a steam bath, it will be easier to get to the entrance due to the fastest melting of snow on the side closer to the south. In addition, it will be preferable if the windows face west, since in the evening the room will be illuminated by rays for much longer.

- It is also recommended to build a sauna from wooden logs for constant air circulation and excellent heat maintenance. When building a foundation, it is better to give preference to a tape structure, since, having the highest strength, it is able to withstand not only light, compact, but also massive structures.

- In no case should you cover the wood with varnish or paint, otherwise an unpleasant odor will be emitted.

To avoid the risk of burns, cover the top of the nails so that they are deeply set. In this case, when the screws heat up, you will not burn yourself.

Interesting ideas for a bath

The interior of a bath is a complex issue that requires a special approach and good imagination. The most popular idea for decorating a bath is a purely Russian style with a massive table and round wooden logs. To decorate the walls, they resort to a variety of forged elements or oak, birch brooms. This will add a significant color to the interior of the bath, bringing its view closer to the face of antiquity. Fans of modernity can install a billiard table, equip a "smoking room" or even a pool, which directly depends on the total area of the bath.

There is a wide variety of materials for finishing the bath, which must meet the following requirements:

- Resistance to temperature extremes and high humidity, which is the most important aspect when choosing any materials for the construction and arrangement of bath rooms.

- Hypoallergenic, health safety. Materials need to be chosen those that will not leave burns on the skin, causing harm, and release toxic substances.

- Attractiveness. The aesthetic design of the premises and the well-chosen interior will attract the eye, pleasing the eye.

- Hygiene. The selected material should be easily susceptible to the action of cleaning agents, while not entering into chemical reactions with them.

- Strength and durability. Materials must be expensive and of high quality in order for the bath to be in excellent external and functional condition for a long period of time.

As for the steam room, deciduous trees are recommended for its design, which do not heat up so that you can easily get burned. In addition, they dry quickly so that no fungus develops on the surface.

- A good example is Linden... This material has a relatively low heat capacity and, as a result, it heats up quickly, however, in contact with the skin, you cannot burn yourself.

- Aspen - strong, durable and high-quality material, which is characterized by bactericidal properties.

- Alder very pleasant to tactile sensations, it is resistant to water of different temperatures - both cold and hot. This material does not tend to react with either alkaline or acidic cleaning agents, so it can be called easy to maintain.

- Another recommended material is abash... This tree is native to hot Africa, from its very tropics. Abash is practically not inclined to heat up even at very high temperatures and become darker under the influence of various factors.

For doors from the log house to the dressing room, conifers will serve as an excellent material, since the room is not hot, but retains heat.

- For example, one of the most popular materials used to decorate carved doors in the dressing room is Pine... Even if it is able to change color a little over time, its advantages will remain efficiency, high strength and environmental friendliness.

- Fir and spruce - practically indistinguishable materials. One of the common features, besides durability, is that no resin is released from them.

Paneled doors, which are one of the most popular types of doors, will also fit well into the interior of a peasant bath. A panel is a part of a door leaf that differs in width or material. Any wood is not suitable for the manufacture of this type of door. Use birch, oak or maple, which are the highest quality wood materials.

The comment was sent successfully.