Finishing the facades of a private house: an overview of modern materials and innovative technologies

As a person is greeted by his clothes, so a house is greeted by the facade. Finishing the facade of a private house forms the first idea of the owners' sense of taste and wealth. However, this does not mean at all that it should be expensive and pretentious.

Finishing can be done from materials of different prices and appearance, it is only important to choose the right one for a particular case. A review of modern materials and innovative manufacturing technologies proves that beauty and quality can be enjoyed.

Features and device

The outer cladding of a building, be it a small country house or an impressive cottage, requires a reasonable approach to the choice of building materials. Facade decoration may be required in several cases.

- Decoration of the building. When a building is erected from practical, but unsightly-looking materials, they try to disguise them with aesthetically attractive "tricks". For example, a house and a bathhouse made of wood concrete blocks (as well as gas silicate blocks, foam blocks, cinder blocks and ceramic blocks) are cheap at cost, but the gray-black rough walls can hardly be called beautiful. They are sheathed with siding or clapboard, and the unsightly structure immediately becomes neat "like a toy."

This modern trend is firmly entrenched in construction, because in this way the total cost of building materials and cladding is much lower than when building a house from brick or timber, and it takes less time. Panel houses, frame baths, all block buildings are also often masked.

- Protecting your home from the negative impact of the environment. Weather conditions can shorten the life of a building at times. Materials get wet, rot, burn out, freeze, overheat and this is not a complete list of problems. They are not characteristic of all, but very many building materials, especially traditional ones.

Wooden houses will never lose their value and relevance, as it is a beautiful and environmentally friendly material. But a moisture-resistant tree is very expensive, and a budget alternative after several decades begins to darken, stains and loses its attractive appearance. It is no longer possible to return such a facade to its original purity, but it is easy to decorate it with modern materials that will look beautiful and protect the tree from further damage. And you can do it yourself.

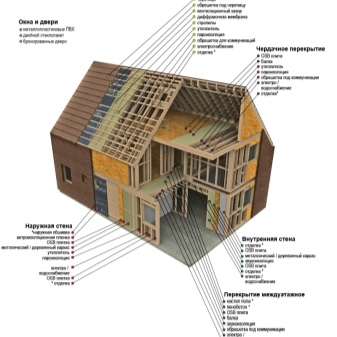

- Insulation of the internal space of the building. It is not only wood that needs protection. All block and porous structures are problematic facades. The fact is that moisture gets inside the pores, and then it freezes, and the house becomes cold. To prevent this, the block façade requires an airtight decorative finish.

Finishing is indispensable when the house is built of deliberately cold materials. These are any prefabricated, panel, frame buildings (including European half-timbered houses), porous bricks, beams and reinforced concrete structures. In the cold season, large heat losses occur through the walls and floor in such buildings. It gets cold inside the room and heating costs rise.

To prevent the problem, it is necessary to sheathe the walls of the building with heat-insulating materials.It is not recommended to do this from the inside, since they "eat up" the space of the room and are not always made from safe raw materials. But it is possible to decorate the walls from the outside efficiently and without prejudice to the usable area inside the house.

In this case, the decorative finishing of the facade plays the role of camouflage and protection. The cladding methods are different, but the goal is the same - it covers the ugly cladding with heat-insulating plates and provides protection from moisture and dust.

A logical conclusion suggests itself: facade finishing fulfills not only decorative, but also practical function. In this regard, many requirements are imposed on the materials: beautiful and fast results, reasonable cost, ease of installation, durability.

Requirements

In addition to the requirements that the owner of a private house is able to present, based on logic and intuition, there are also technical standards. All of them relate to two areas: compliance with GOST and compliance with SNiP.

- GOSTs for each type of cladding are different. Compliance with them in the production of material is important, since the standard defines the minimum acceptable quality of the material. It regulates the composition of the substance, the permissible amount of resins and chemicals that are harmful to health, the strength of the material and methods of its verification, resistance to weather conditions and mechanical stress, storage rules and methods of transportation.

- SNiP, in turn, control the safety of the use of materials. The main selection criterion is the fire resistance class. Materials that support combustion but are not flammable are acceptable, and non-combustible options are best. This applies both to the cladding and to the intermediate layers for thermal insulation - mineral wool, polyurethane foam, finishing with expanded polystyrene and other heaters.

Also, building codes describe the permissible weight load on the structure of a building so that it remains safe for life and health. It will be different, for example, for one-story brick cottages and two-story frame buildings. It is important to consider the requirements for a specific type of building.

The competent use of materials is also in the area of building codes. It is not enough to decorate the facade of a cold house with mineral wool and sheathe it with siding on top. It should be borne in mind that when installing thermal insulation, waterproofing, vapor barrier and a ventilation layer are also required. If you do not follow these rules, the effect of finishing will be negative.

Requirements for the design of finishing materials should be placed in a separate category. Unlike GOSTs and SNiPs, they are not officially fixed on paper and are advisory in nature, but they are also important.

The facade decoration of the house affects the landscape design and the appearance of other buildings on the site, so the materials must be chosen so that they look harmoniously against the background of the surrounding objects. A Scandinavian-style house in the middle of a Japanese rock garden is an unfortunate combination, but finishing with natural materials for a chalet-style house surrounded by a country garden is a winning combination. The emphasis on naturalness and simplicity makes it correct.

Advantages and disadvantages

Facade decoration as a type of repair and construction work has its advantages.

- Some of the modern materials are designed for the inexperienced user. On the packaging of paints and varnishes there are detailed recommendations on the choice of tools for application, the set of siding panels is supplemented with step-by-step assembly instructions, wooden and plastic lamellas have a simple locking system that is assembled like a designer.

- With the help of finishing materials, any facade acquires a neat decorative look. It can be a new block house or a wooden structure from the last century. The cladding with new material will give it a modern, neat and beautiful look.

- Insulation and insulating materials can be hidden under the decorative cladding

- A variety of shapes, colors and textures of finishing materials makes it possible to decorate the facade in a certain style.

- Imitation of expensive materials from more practical raw materials saves the budget of home owners.

- The decorative finish can be changed as it wears out, and with it the look of the house will change. Thus, it will always be in line with fashion trends.

- Science and manufacturing continue to evolve. The quality of materials is naturally improving. If two decades ago, flammable sawdust and wet foam rubber were used for rough wall cladding, today they have been replaced by safe OSB plates and sprayed polyurethane foam.

Now let's talk about the cons.

- Finishing work always requires preparation of the base. If you plan to paint the walls, they must first be primed and leveled, if sheathing, the installation of the lathing is needed. These activities require additional time, money, and sometimes skill. Not every home owner is capable of handling a paintbrush and building level equally well.

- Manufacturers of building materials are often cunning, saying that their material is so simple that an unprepared person can work with it. This leads to the fact that home owners are superficially familiar with the installation technology and make many mistakes. These mistakes nullify all efforts: the casing leaks, does not keep warm, and is easily damaged. It is especially difficult to work with hard-to-reach places and protruding parts of the structure: window openings, attics, balconies, foundations.

- Many materials cannot be reused. If a gross error was made during installation, the cladding fragment will have to be replaced with a new one.

- Not every cladding can be repaired. For example, plaster and paint can be easily repaired where it has chipped, scratched or dirty, and plastic or wood panels will have to be disassembled entirely if one element in the structure is damaged.

- Not all materials are budgetary. Various chipboards, paint, plaster, siding are available for any budget, but finishing with stone or precious wood is an expensive pleasure.

Varieties

Options for finishing the facade of a city or country house are varied. Some materials are suitable for do-it-yourself repairs, others require professional intervention. In both groups, specialized types can be distinguished, which are intended specifically for facade decoration, and borrowed materials. They are often combined. So, along with the use of plaster, there can be a cladding of the facade elements with a profiled sheet, and flat slate is combined with a stone.

A review of popular materials will help you make the right choice.

Painting

About 20-30 years ago, painting the walls of a house was the easiest and fastest way to decorate and belonged to the "cheap and cheerful" category. Modern paint for outdoor use is budgetary only in comparison with more complex materials: tiles, bricks, wood. The paint finish itself has become more complex, but the result is also more durable.

Let's consider the advantages of paint for decorating the facade.

- Suitable for all types of surfaces. It fits equally well on wood, brick, plaster, new and old materials.

- When processing wood and bricks, many types of paints help to show their texture. This is important for loft-style and eco-friendly design.

- There are many application options: rollers, spray gun, paint brushes. You can work without preparation.

- It will take just a day to process the facade.

- Paint is a convenient material for creating a decorative effect. She can apply a drawing, highlight individual elements of the facade, combine colors to visually change the architectural appearance of the house.

- Modern exterior paints protect the facade from decay, moisture, dust, rust on metal elements.

- The painted facade can be washed.

- The paint does not fade for a long time. The service life is on average 10 years, then the color needs to be updated.

- On top of one coat of paint, you can apply another 5 to 10.

Paint has its drawbacks as well.

- The paint is liquid, therefore it is easily absorbed into porous surfaces and wood. This leads to a large waste of material.

- For staining, a prepared surface is needed. The facade must be cleaned of old paint, if any, dust, degreased, primed in two layers, and sometimes even with plaster. This is a long process, some of its stages require painting skills.

- One can of paint is cheap, but the front of the house is large and the paint is applied in two layers. As a result, the budget cost is a relative bonus.

- For the facade, paints are usually not water-based, but their distinctive feature is the pungent smell of chemistry. Not everyone can work with him.

- Some types of paint cannot be washed. They get dirty and lose their gloss in 2-3 seasons. When choosing, you need to be careful.

The options for coloring compositions are varied. They can be divided into three groups.

- Water dispersion paints. These are non-toxic, quick-drying formulations that can be diluted with water. Some of them are universal and are diluted with white spirit and other organic solvents.

Water-based paints include inexpensive formulations based on vinyl, acrylic, and silicone-based coatings. Compositions based on silicone are considered the most suitable for facade work. They have all the necessary properties: from good adhesion to the wall surface to water resistance. The coating is not afraid of moisture or fire. It lays down on any surface in an even dense layer.

- Mineral paints. This group includes substances based on natural minerals: lime, potassium, cement.

Lime dyes are gradually becoming a thing of the past. They are inferior to other species in the stability of the coating and their only advantage is their low price. For the same reason, alkyd paints have become obsolete. Paints based on liquid glass (potassium processing product) perform well in operation, but it is difficult to work with them. They require careful preparation of the substrate and dexterity. Cement paints are easy to work with, look beautiful on the facade, vary in color, but begin to peel off faster than others.

- Rubber paints. Latex in their composition provides a dense, even, moisture resistant coating. They have high adhesion to the surface. The dried paint has a washable surface and retains its color for a long time. This is the most expensive, but the most effective option for the facade.

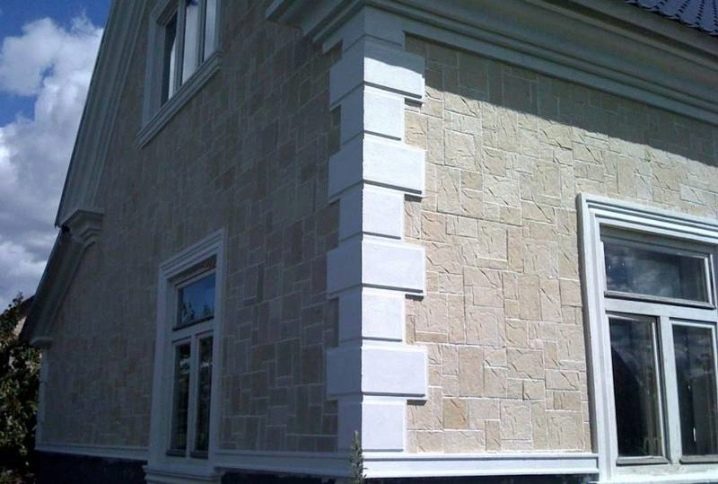

Plaster

Plastering the walls of the facade occupies a leading position among the types of finishes. There is an explanation for this: the coating is cheap, and the result is excellent.

The method has a number of advantages.

- The plaster is not afraid of moisture. It contains plasticizing substances that make it durable and water-repellent.

- The pigment is “embedded” in the mixture, so it starts to fade only after a few years and fades gradually. There will be no obvious burnt-out and bright spots on the surface of the walls.

- The coating does not deteriorate when the ambient temperature changes.

- Plaster breathes.

- The material is malleable in work.

- The mixture is sold ready-made at an affordable price.

- It closes microcracks and irregularities on the walls, is both a base and a decorative layer.

- Plaster mixes have a huge potential for facade decoration. You can choose a mixture with decorative additives (coloring pigment, glitter, marble chips), a composition for textured or structural finishing.

Decorative plaster makes it possible to imitate expensive materials: marble, stone.

Structural plaster is a mixture for creating a non-uniform surface.Popular reliefs are "bark beetle", which imitates the grooves inside the wood, eaten by the bark beetle, and "fur coat". A fur coat is the granular surface of the plaster, which in appearance a little resembles the wet stuck together pile of a paint roller.

Textured plaster is designed to create volumetric decor, for example, imitation of stucco molding:

- the relief can be created with improvised means: rollers, stencils, using a crumpled plastic film and foil, a spatula, brushes;

- a thick layer of plaster (can reach 10 cm) improves heat and sound insulation in the house.

Consider the drawbacks of the material.

- Careful preparation of the wall surface is required.

- In case of improper preparation, dilution of the mixture with water, application with a too thick layer, absence of a primer composition, the coating may swell, crack or peel off.

- The plaster hardens quickly in the container, but dries for a long time on the surface of the walls. Finishing in one layer needs to be completed in a few hours, it is difficult without skills. But for complete drying it may take from 7 to 30 days.

- The maximum thickness of one layer is 5 cm. If the layer is larger, the coating will crack due to uneven drying. The second coat can only be applied over the primer and the primer after 4 weeks.

- Working with plaster requires suitable weather conditions: from 5 to 20 degrees, without rain or heat.

There are several types of plaster: mineral, acrylic and silicate. The first and second types are universal, and the silicate mixture is intended for porous surfaces. On brick and block walls, it creates a dense protective film without interfering with the vapor permeability of the materials.

Siding

Siding is an alternative budget option to painting and plastering.

Siding has a number of advantages over other materials.

- Low weight. Lightweight prefabricated panels are suitable for the finishing of solid structures made of wood, block, brick, reinforced concrete slabs and for houses, the structure of which is not subject to heavy loads: frame, prefabricated.

- Two people are enough for installation.

- Low price compared to natural materials.

- The panels can be conveniently mounted over thermal insulation. It also improves sound insulation performance.

- Improves sound insulation in the house.

- The top layer of the panels is water-repellent, it can be washed with water with the addition of chemicals.

- Wide temperature range: from -50 to + 50 ° C. Suitable for different regions of the country.

- The panels retain their color for decades. Siding parts are molded from a substance called a compound. It includes various components, plasticizers and coloring pigments. Due to this, the dye is “embedded” into the structure of the material and is not washed out from it.

- A wide range of colors and textures. The relief and color can imitate wood, brick, stone and other materials.

- Easy to dismantle to change finishes.

- Facade decoration is neat and stylish.

Minuses:

- saturated color panels are less protected from UV rays, are prone to fading;

- siding is subject to thermal expansion;

- low impact resistance, panels can break from a strong impact, and they also remain scratched;

- the material supports combustion (except for metal siding);

- it is difficult to finish the embossed facade;

- installation of the lathing is required.

The types of siding are varied. There are about a dozen panels made of various materials and alloys.

- Vinyl siding. The most popular and widespread due to its versatility. It has several varieties: classic (horizontal and vertical), basement and ship. The basement is needed to decorate the lower part of the building, and the ship's one is different in that it looks like ship boards.

- Acrylic. It is distinguished from other types by its improved characteristics in all respects.Withstands the coldest and hottest climate, does not burn, is additionally protected from ultraviolet radiation, the warranty period and price are higher.

- Metal. This name unites types of panels made of copper, aluminum and sheet steel. Metal siding is less flexible but more durable. It can be painted, it is protected from corrosion, non-flammable, it can have a decorative coating like wood or stone.

- Woody. Rarely used for decoration. It tolerates moisture worse, burns, has the shortest service life, but is expensive due to its presentable appearance.

- Cement or concrete. For its manufacture, raw materials are various mixtures based on high-quality cement with the addition of minerals, plasticizers, dyes. A protective layer is applied on top. A mixture is used to create an imitation of natural stone.

The products look beautiful and are cheaper than stone. They are not afraid of moisture and sunlight, but the top layer is brittle and easily chipped off. The weight of cement siding is large. You need a lathing with the expectation of an additional load.

Slabs

Cheap finishing materials include all types of boards based on wood chips and fibers.

For house cladding, predominantly cement-bonded, oriented strand and structural insulating panels are used.

- For CBPB, small wood chips, Portland cement and chemical additives are used. Such plates are durable, fire-resistant and water-resistant, do not rot, insulate well the interior space of the house, and "breathe". A complete finish is not considered. Their surface must be painted or plastered.

- DSP-plates - heavy, from 10 kg. This makes it difficult to install the upper part of the facade and puts a lot of stress on the battens.

- OSB boards are made from large fragments of wood, they are glued together using resins and synthetic waxes. They are cheap, reliable, and outwardly similar to the texture of solid wood planks. With all the properties, DSPs differ in their lower weight.

- SIP panels are a kind of "pie" of two OSB boards with a polystyrene interlayer. The material combines the advantages of OSB-plates and expanded polystyrene as insulation and sound insulator. It weighs a little more and costs more. Serves as a good base for decorative paint or plaster in the future.

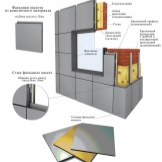

Sandwich panels

In terms of operational characteristics, these panels are similar to self-supporting insulated wire, but differ in that it is a little easier and faster to sheathe the facade with them. Sandwich panels are a three-layer structure: base, heat-insulating layer, front panel. Expanded polystyrene or cotton wool (mineral, fiberglass, basalt) is used as an insulation layer.

The outer surface is made of different materials. It can be polyester, universal in its properties, a layer of PVC or polyurethane foam, drywall, galvanized steel or aluzinc. Of the plastic coatings, polyester is best suited for the changeable Russian climate. Good in use and drywall. It has all the technical parameters for exterior decoration and transforms the facade of the house.

Advantages of sandwich panels:

- 3-in-1 material: thermal insulation, noise insulation and a beautiful exterior finish, no additional steps for laying steam and waterproofing are required, ventilation is provided inside the panel;

- the panels are lightweight, they are convenient for finishing both the upper and lower part of the facade, you can work alone;

- a beautiful and neat appearance of the facade is provided;

- panels are bio-resistant, not afraid of moisture;

- installation is carried out in all weather conditions;

- wide range of colors.

Disadvantages:

- monotonous design;

- panels are difficult to cut and fit in hard-to-reach places;

- you need to process the joints;

- the front panel of steel rusts;

- the material is flammable;

- the panels may be damaged during installation.

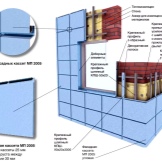

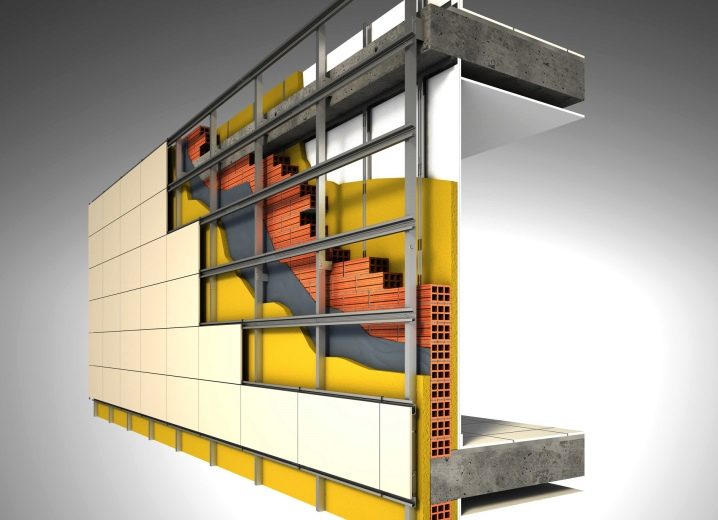

Suspended structures

Finishing work using hinged ventilated facades has a lot in common with sandwich panels, but the latter are cheaper.Suspended structures without fail include a frame made of metal profiles. The empty space is filled with insulation, vapor barrier and waterproofing materials. There is a ventilation gap between the wall and the frame, as well as between the waterproofing and the inside of the curtain panels. It is necessary for the materials to perform their functions, condensation, fungus, frost does not appear on the walls of the facade.

Suspended structures are not a specific name for a finishing material, but a collective characteristic of their group. They can be wooden, metal, vinyl, natural and artificial stone, rare raw materials (clinker bricks, tiles, glass, fiber cement). Wooden panels are made by pressing wood fiber with special shrinkage. Additional components increase the resistance of wood to high humidity and environmental influences. The result is a moisture-resistant, durable, environmentally friendly, easy-to-assemble coating.

Wooden ventilated facades require treatment with protective equipment, are classified as combustible materials, and are more expensive than analogues made from other raw materials. But the appearance of the finished finish is the most powerful argument in favor. Vinyl facades are similar in their characteristics to vinyl siding. At a relatively low price, you can purchase an option from a large assortment of colors and textures that imitate various materials. It is easy to care for, resistant to changeable weather conditions, and will delight the eye for decades.

Metal panels and imitation of natural materials are also close in their characteristics to siding panels.

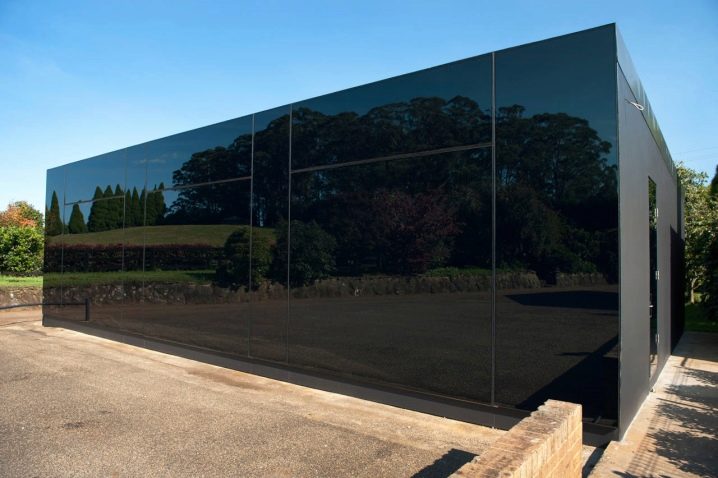

But glass structures have no analogues. These are panels that are made on the principle of double-glazed windows.

Their advantages:

- original view of the facade;

- heat insulation and sound insulation at a high level, which is provided by a special arrangement of double-glazed windows;

- tinted glass protects the wall of the house from overheating;

- the thickness of the double-glazed windows allows you to decorate the frame house with glass panels without the use of additional materials, that is, from the inside it will have transparent walls, and from the outside - tinted or mirrored;

- strength;

- absolute moisture resistance;

- do not fade;

- serve for about 50 years.

Disadvantages:

- professional skills are required to work with double-glazed windows;

- additional measures are needed to create the tightness of the finish;

- heavy weight of the structure;

- high price;

- the facade will have to be washed regularly.

Block house

A type of ventilated curtain wall. The panels are made in the form of logs on the front side. When the façade is fully lined with semicircular paneling and matching decor, the house looks like a fresh and clean log cabin. An alternative to a block house is a raised beam. These are panels with imitation of natural board cladding. It has no pronounced relief.

Wood

The last variety of wood finishes is solid wood panels. They are not very popular, since the weight of one-piece parts is greater than their imitation from shavings and plasticizers, as well as the price, and the performance characteristics are inferior to more modern materials. Natural wood for facade cladding must be chosen according to such characteristics as biostability and water resistance, otherwise the material will quickly lose its appearance and begin to deteriorate. The most practical option is to decorate the façade with larch, teak or oak lamellas. Birch wood should be avoided. It is furniture and is not suitable for outdoor use.

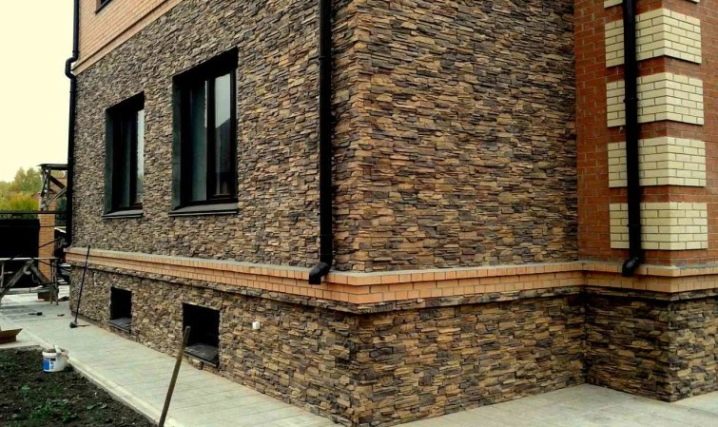

Stone

Decorative stone finishing is more difficult and more expensive than other methods. Installation requires accuracy, patience and finishing skills. Facing plates with a relief or smooth surface on the cut are made from various natural raw materials. The most expensive is decorative marble or granite. It is also the most difficult in terms of installation and design.There is a risk of choosing the wrong color of marble or the size of stone fragments, and the facade of the house will turn out to be gloomy and ponderous, rather than elegant.

Limestone, rustic rocks, gabbro-syenite, quartzite, dolomite and porphyry are often used for finishing. Facades are trimmed with sandstone, slate and travertine. Finishing material is presented in various formats: euro tiles, dies, fur coats, slabs, wild stone. The Euro tile has the same size and smooth face. Dies differ in size from tiles, they are made from scraps and are 2 times smaller in area. The thickness is the same - 20 mm. "Moscow fur coats" are plates with a pronounced relief on the front side. Most expensive format.

Slabs are carved from a solid block, and the wild stone is as close to its natural form as possible. Its edges are slightly rounded, and the thickness is cut to a maximum of 2 cm.

Stone advantages:

- the stone facade speaks of the prestige of the owners of the house, not everyone can afford such a high cost;

- environmentally friendly material;

- the color palette consists of natural natural shades;

- has all the necessary characteristics for the facade: it is not afraid of moisture, sun, dust, does not crumble;

- improves heat and sound insulation;

- durable coating for decades.

Disadvantages:

- laborious finishing process;

- heavy weight and load on the facade;

- high cost of finishing a square meter of surface.

Brick

This building and cladding material at the same time, made in the form of separate blocks, and not fake panels, is able to revive the appearance of the facade, even in the most neglected case.

Brick has excellent performance as a finish:

- the facade takes on a fresh, well-groomed look;

- thermal insulation and noise insulation in the room is improved;

- the material is shockproof, resistant to damage, not afraid of moisture, does not burn;

- long service life.

There are many disadvantages of brick decoration:

- certain weather conditions are required, the masonry will turn out to be of poor quality at sub-zero temperatures;

- you need experience with mortar and brick laying technology;

- finishing the entire facade is an expensive pleasure;

- the total weight of the facing layer is a colossal additional load on the foundation.

Bricks vary in size, color and texture. Popular are small red bricks with a porous structure, as well as smooth ceramic products of red, beige, brown, graphite colors.

Clinker tiles

Clinker tiles are actually a synonym for the word "ceramic", only they are more durable. Clinkers are made from plastic clay.

In the process of pressing and firing at temperatures above 1000 degrees, it acquires its positive qualities:

- the minimum level of water absorption is no more than 5%;

- wear resistance;

- resistance to frost, moisture, fire;

- uniform tone throughout the entire thickness of the clinker, which makes microdamages, scratches and chips on the surface invisible;

- a variety of textures and colors, there are tiles processed, glazed, raw, textured, patterned, combined, the color range is as diverse as possible.

Tile is cheaper than stone, and the result is quite similar. Installation requires finishing skills.

Brands

The concept of "quality material" by default means a bona fide manufacturer. There are many companies on the domestic market that have already earned a name and consumer confidence, but there are also many brands with low-quality goods. Targeting popular brands that regularly receive positive reviews from professionals and hobbyists will help simplify searches.

- Good quality facade paints are produced by companies Belinka, Alpina, Tikkurila, Senezh, Yaroslavl Paints... They retain their color for a long time and protect the façade walls.

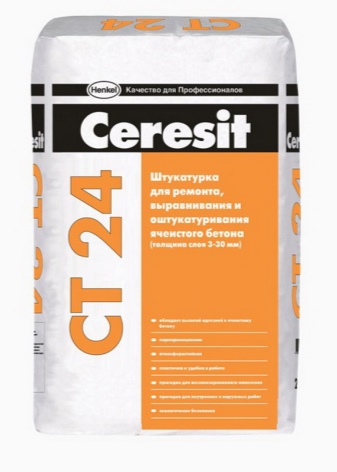

- The undisputed leader in the production of plaster - Knauf brand... An exterior plaster that meets all technical requirements is available in the Rotband line. Ceresit products are no less popular. Ceresit is a Henkel product.

- Boards based on wood chips can be safely purchased from a domestic manufacturer. Many countries buy raw materials in Russia and then multiply the price for exports, imports, brands and customs duties. A similar quality at a low price is present in small industries: Hillman, Kalevala, Tamak, Svir.

- High-quality SIP panels and materials for heat and waterproofing are produced by TechnoNICOL.

- Composite panels of excellent quality - from the company Alucobond.

- Brick can also be purchased in excellent quality from many Russian manufacturers: Tellura, Stone, Gzhel brick factory etc.

- Among siding manufacturers, they speak positively about European firms. Vinyl-On, Mitten, Russian subsidiaries of Döcke, St. Petersburg company Nordside.

- Clinker tiles are recommended to be purchased from German companies. ABC, FerdhausKlinker, Roben.

- Leaders in the production of facing stone: Camelot, Forester, WhiteHills, Terracotta, Brixtone.

All of these manufacturers specialize in the production of materials for construction and repair, and complementary elements and tools (solvents, cement, brushes, painting tools, etc.) related to finishing can also be purchased from them. In some cases, this is of fundamental importance. For example, many siding manufacturers reduce or completely void the warranty period if components were used during assembly from another manufacturer.

Professional advice

Various factors influence the choice of materials for facade finishing. The operational condition of the work surface, the architectural style of the house, the surrounding space, and the climate in the region are important here.

In order to revet a facade with a suitable material, it must be selected taking into account the recommendations from professionals in the field of construction and renovation.

- Modern materials are a priority. New technologies open up more opportunities for the production of building materials. Why not stop choosing solid wood, which was prized above only decades ago, and replace it with the block house that is relevant today?

- Preparing your work surface is just as important as the finish itself. A bad base will ruin the painting and plastering finishing work. The materials will simply peel off or crack as they dry.

- The composition and properties of the material are indicated in the accompanying documentation for a reason. They need to be studied. Otherwise, you can finish the walls with glass fiber concrete, and after a season you start to wonder at the fragility of the material.

- Suspended structures are always mounted on the lathing.

- The most expensive finish is not always the best, the cheapest is not always the worst. It is necessary to take into account the climatic conditions.

- When working with any kind of facade panels, it is important to remember that materials are prone to thermal expansion. Therefore, do not drive and screw the fixing elements into the panel itself. First you need to drill a hole.

- When choosing a design, you need to be guided by the idea of how the house should look after renovation. Youthful, businesslike, austere, modern, or purposely aged?

- It is imperative to take into account the color, material and shape of the roof. Visually, it is a single whole with the facade.

- The house cannot be viewed in isolation from the surrounding landscape and objects. You need to strive for a harmonious combination.

- From time to time, you need to take care of the finish: remove dust, renew color, wash, protect with special means.

Beautiful examples

When choosing a facade design, you can rely on a bright color, embossed texture, accents on individual details or bold combinations of materials.

A luscious and vibrant palette available with paint, plaster and vinyl siding. Such a house will look modern and fresh.

The textured finish will be calmer and more noble. The most realistic imitation of wood, brick and stone, cladding with natural stone and tiles are welcomed here.

It is convenient to highlight window openings and doors, balconies and decorative elements as accents. They can be made in contrasting colors with the walls of the house, to highlight not only the windows, but also the area around them with a different shade.

Bold combinations are: plaster and stone, glass and metal, brick and stainless steel, clinkers and French forging, stucco and marble.

An overview of the facade decoration of a private house with your own hands is waiting for you in the next video.

The comment was sent successfully.