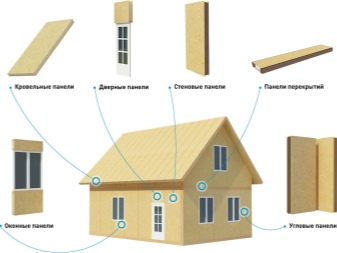

House kits from SIP panels

Those who decide to build a house quickly and not very expensively may pay attention to home kits made of SIP panels. Accelerated construction takes place due to ready-made numbered structures coming to the construction site directly from the factory workshops. The only thing left for builders is to put together a house from this "constructor". In turn, SIP panels will provide the new structure with reliability, excellent heat saving and sound insulation.

Peculiarities

Although the construction of houses using SIP panels has been mastered not so long ago, work on the creation of a decent heat-insulating kit has been carried out since 1935. Today, factory-made home kits are reliable, well-proven products. They have a lot of advantages that you should pay attention to:

- a house built of SIP panels six times warmer than a stone one;

- he is not afraid of seismic shocks of more than seven balls;

- it can withstand a load of up to ten tons (vertical);

- the building material is relatively light, so the house does not need a too expensive foundation, a pile or pile-grillage is enough;

- the panels have good heat and sound insulation;

- only non-combustible materials are used to create them;

- SIP panels consist of environmentally friendly components harmless to humans;

- the small thickness of the walls saves space for the internal space of the house;

- during construction, no heavy special equipment is needed;

- assembly takes place quickly and in any season, without frost restrictions;

- the built building does not shrink, you can immediately start finishing work;

- a built house will cost significantly less than a brick one.

What does it consist of?

House kits are ordered for self-assembly (summer cottage), for houses of different storeys, industrial workshops. During checkout, you can choose the basic or advanced option. The standard set has the following configuration:

- strapping timber for wall fastening;

- directly the wall SIP panels themselves;

- all types of floors - basement, interfloor, attic;

- internal partitions;

- rough board;

- fasteners.

The extended house kit may include custom-made reinforced internal partitions, cladding siding, windows, doors, drywall for interior use. Supplements are discussed directly with the construction team.

It should be remembered that everything necessary for the foundation and supply of communication systems is not included in the overall package.

Materials (edit)

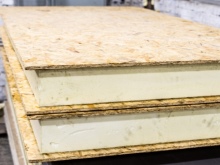

Structurally, SIP panels are simple and straightforward - the target filler is laid between the two facing layers. But do not confuse them with sandwich panels, which are arranged in the same way. All components of the self-supporting insulated wire structure are as rigid as possible and capable of withstanding a huge load, only they are suitable for the construction of buildings. Sandwich panels are used as a finishing or auxiliary material.

Often, users who decide to build a house using SIP composites wonder why prices differ so significantly for them? The answer is simple - it all depends on the types of materials from which the structure is assembled. Before purchasing, you should familiarize yourself with the documentation, which indicates the composition of the product. To get a deeper insight into the topic, consider what materials go to the outer, inner and connecting layers, and then talk about the finished types of panels provided by manufacturers.

Outer layer

The outer, facing layers of SIP panels, between which the filler is contained, are made of the following materials.

- OSB. Oriented strand board, assembled from many layers of shavings, bonded with adhesives. The chips in the layers have a differently oriented direction - inside they are laid transversely, and on the outer surfaces of the slabs longitudinally. This manufacturing method makes it possible for OSB boards to withstand powerful loads.

- Fibrolite. Boards are made from wood fiber. On machines, the wood is dissolved into long strip-like thin shavings. Portland cement or magnesia binder is used as binders.

- Glass magnesite (MSL). Sheet building material based on magnesia binder.

Heaters

A heat-insulating layer is laid between the facing plates; it also performs the tasks of a sound insulator. For the inner filling of SIP panels, the following types of filling are used.

- Expanded polystyrene. In SIP panels, this material is most often used. Types with the abbreviation "C" (not subject to combustion) and a density of at least 25 kg per cubic meter are used. The material is lightweight, retains heat well.

- Pressed polystyrene. It has a high density, enhanced noise insulation, low thermal conductivity. In SIP panels, they are used less often, since it is more expensive than free-foam polystyrene.

- Polyurethane. It has improved thermal insulation properties, but belongs to the most expensive heaters.

- Minvata. It is used in conjunction with OSB, but not often, since the material can shrink.

Connections

Manufacturers, for bonding SIP panels, use several types of adhesives that provide a high level of adhesion:

- German glue "Kleiberit";

- one-component polyurethane adhesive for Sip-panels "UNION";

- Henkel Loctite ur 7228 polyurethane glue.

All elements and binders, joining under high pressure, form the most durable panel, which is used for the construction of buildings.

Based on the above materials, manufacturers assemble and produce finished products.

- OSB and expanded polystyrene. Lightweight, durable and reliable material is used for the construction of private houses and outbuildings.

- OSB and polyurethane foam. They are used for the construction of industrial workshops, but sometimes slabs are also purchased for private construction. In case of fire, it does not burn or melt, it becomes liquid and flows down from the walls. In terms of thermal conductivity, it doubles polystyrene foam. The material is not afraid of insects and rodents, it is environmentally friendly and durable.

- OSB and mineral wool. Sip panels in this version acquire vapor-permeable, "breathing" properties, in contrast to expanded polystyrene. But the mineral wool itself cannot give special strength to the panels and over time it begins to shrink.

- Fibrolite and polyurethane foam. They are used not only for load-bearing walls of buildings, they are used to build gazebos, garages, baths, since the material does not burn, is not afraid of insects, strong and durable.

Manufacturers

In Russia, many factories are engaged in the production of house kits from SIP panels. You can always find a company with a good reputation and location in the region of the planned construction. We suggest that you familiarize yourself with several companies that have proven themselves well in this area.

- "Virmak". The production is deployed on modern high-quality equipment. The company supplies sets of any number of storeys, regardless of the purpose and footage of buildings. Sip panels are made on the basis of concrete, and not chips (using CBPB technology), which guarantees greater strength, reliability and durability.

- Novodom. Quickly and efficiently, according to an architectural project, a constructor for the future home is produced. It is made from reliable and durable materials, with a reasonable price-quality ratio.

- "Leader". The company offers kits for the most favorable prices and their delivery throughout Russia.Provides the necessary design documentation. For residents of central Russia, it is possible to install a house, starting with the foundation and ending with finishing work.

How to choose?

When deciding to build a house from SIP panels, you should study the features of house kits and pay attention to a number of points.

- Find out the composition of SIP panels, understand whether the proposed layout suits.

- The thickness of the material should be 120 mm for a one-story building and more than 124 mm for a two-story building.

- It is better to purchase prefabricated and cut house kits. Cutting at the construction site does not guarantee high dimensional accuracy.

- You can order internal partitions of the house from thinner materials, this will significantly save your budget. But it is impossible to reduce the cost of the project on load-bearing walls.

- Construction from SIP panels is carried out in the cold season, if you order house kits from the manufacturer in winter, you can count on discounts.

A house from SIP panels is erected in a period from a month to six months. The process will speed up the selection of four-meter products designed for a large building. Manufacturers promise that such houses can stand up to 80-100 years without major repairs.

The comment was sent successfully.