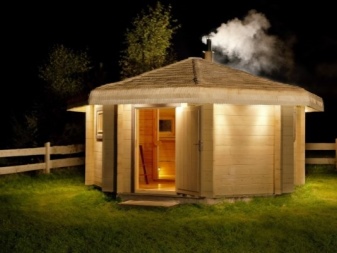

All about aspen baths

A private bath is the dream of many owners of private houses. This is a great place to relax and rejuvenate. For its construction, wood of different varieties is used, each of the types has certain characteristics. The article will focus on aspen baths.

Pros and cons of the material

Aspen saunas have many positive qualities.

-

This type of wood is not afraid of mold, mildew and rotting. This is an important characteristic for the building material of a bath.

-

Aspen does not emit decay products.

-

The material does not absorb water.

-

The array is resistant to high temperatures. No resin evolves when heated.

-

Natural raw materials attract attention with their enchanting aroma - it creates a pacifying atmosphere in the room. Due to this characteristic, aspen is often called "honey tree". Regular visits to the aspen bath improves physical condition.

-

After drying, the building material becomes resistant to attacks from harmful insects.

-

The solid wood boasts a long service life, provided that it has been harvested with high quality standards in mind. In order for the product to obtain certain characteristics, the wood must be properly processed.

Due to these characteristics, aspen is great for building a bath.

Now let's look at the disadvantages of this type of wood.

-

Although the tree looks healthy, there may be rot on the inside. Such a product is not suitable for building.

-

It is possible to harvest a blockhouse only from the upper part of the trunk, which complicates the process of harvesting lumber.

-

Due to the high moisture content of this grade, softwood shrinks a lot. The natural drying process leads to cracks and deformation.

-

It is necessary to harvest wood only in the spring. At other times of the year, it is almost impossible to remove the bark from aspen.

-

After the drying process, the material is compacted, which makes it difficult to work with. It is very difficult to chop it up yourself.

-

Aspen is more expensive than other common types of wood. Rotten lumber infects healthy planks and logs, which is why the percentage of rejected material is very high.

-

The appearance of the material cannot boast of high aesthetic qualities. Stains and dark areas often appear on the surface of the wood. It is necessary to carry out additional work to increase the attractiveness of the product. Woodworking workers use antiseptics, varnishes, enamels and other compounds. And also does not do without grinding, sanding and other processes.

Comparison with other breeds

Aspen is often compared to other varieties such as linden, alder or pine. Each tree has a certain set of advantages and disadvantages that must be taken into account when choosing a building material for a bath or when buying furniture for a steam room.

Most often, aspen is compared to a linden tree, which has many positive features.

-

Linden is easy to process and has a soft texture. This greatly simplifies the building process.

-

The tree heats up quickly and maintains the required indoor temperature. This is facilitated by low thermal conductivity.

-

If the drying process has been carried out correctly, the logs retain their shape and do not shrink. The building can be used immediately after being built.

-

This is a versatile and common option that does not require cladding using lining.

-

The wood has a delicate and delicate aroma, which creates a favorable microclimate inside the room. Water procedures inside such a bath have a positive effect on health.

For these reasons, some believe that linden is better suited for building a bath, however, it also has its drawbacks.

-

The main disadvantage is a weak resistance to decay. Even careful processing does not save from this disadvantage. Fungus and other harmful microorganisms can develop on the surface of the wood.

-

The low density of wood fibers leads to the need to regularly repair the building, replacing part of the lumber.

-

Linden is expensive. The price of the material is higher compared to pine and spruce. And also the material will cost more than aspen.

-

Another disadvantage is the large amount of resin emitted. This characteristic is not suitable for the material used in the construction of the steam room.

The second competitor of aspen is alder. Black and gray alder are used in the woodworking industry. Natural raw materials are often used for the manufacture of Euro lining.

Wood has some positive characteristics.

-

The material has astringent and disinfectant properties.

-

Alder has become widespread due to its unique healing qualities, which is why it is often chosen for the construction of baths and saunas. The substances contained in wood fibers begin to be released during heating. They have anti-inflammatory, hemostatic and other effects.

-

This is a popular and common wood variety that is easy to find in any hardware store.

A number of characteristics are noted as disadvantages.

-

Unlike aspen, the material does not respond well to high soil moisture. For this reason, alder cannot be used for flooring.

-

The variety has low elasticity.

-

Due to insufficient strength, wood must be handled very carefully.

The last species to look at is pine. Experts identified some factors as positive qualities.

-

Under the influence of high temperatures, phytoncides begin to be released into the air. These substances have a positive effect on human health.

-

Pine has an amazing pattern that lasts for a long time. Long-term processing is not necessary to make the lumber look attractive.

As disadvantages, the stuffiness that fills the steam room when heated is noted. Large amounts of resin are also inconvenient. The thick substance often causes burns or sticking.

Pine wood is considered to be of higher quality compared to aspen for the reason that only every 20 harvesting unit is considered unsuitable for construction. The use of softwood is more profitable from a financial point of view.

Materials used

To build a bath, you can use various types of lumber.

Whole log

Hand-cut logs are great for building a classic Russian bath. But this type of natural material is characterized by high humidity, up to 85%. This leads to increased drying costs. After processing, the wood dries out, loses its density and decreases in size. All this affects the price.

If you decide to build a sauna from logs, choose only a high-quality and ready-to-use product.

A properly designed log house will help to securely fix the lumber.

Beams

The bath can be built from a bar. The procurement of this material is carried out seasonally. Natural raw materials undergo a mandatory drying process using special chambers. Less time and money is spent on the manufacture of timber compared to harvesting logs. At the same time, the quality of the product is maintained.

For finishing

Euro lining made of aspen wood is perfect for covering a bath. It has an enlarged groove (up to 8 millimeters) and a ridge. This characteristic indicates the strength and reliability of the connections. During the operation of the building, the risk of cracks is significantly reduced. And also the spliced lining has become widespread.

The lining is divided into groups depending on the quality level. The product labeled "Extra" is the most expensive. And also manufacturers use the designations "A", "B" and "C". If you want to sheathe the room with wood material without knots and defects, choose the first option.

Note: boards are also made from aspen, as well as other types of finishing materials. All products are presented in a wide range.

Aspen furniture and other elements

Aspen is used to make not only building material for the bathhouse, but also furniture and other interior elements. A bench made from natural raw materials will look great indoors. You can add shelves, curtains, a font, a table and other products to it.

For the production of quality furniture, material is used that has undergone a long processing procedure. The tree is impregnated with an antiseptic and special polymers. However, many manufacturers believe that when working with aspen, such processing is not necessary due to the special composition of the wood itself.

Wood fibers contain substances that prevent decay and protect natural raw materials. Even under the influence of high humidity, the raw materials retain their declared qualities.

You can also install aspen doors in the bathhouse. They will look great in combination with the floor and ceiling of the same type of wood. The aspen bench will become not only a stylish decoration for the steam room. Due to the special heat exchange, painful sensations upon contact with furniture are excluded.

With the tools and experience, you can make your own furniture. If you steam the wood thoroughly, it is easy to process. Shop and other handicrafts can be ordered from the master.

Such furniture will cost more than finished furniture, but it will add personality to the interior.

Building Tips

Experts who have been working with this type of wood for a long time share their recommendations with beginners.

-

The optimal age of the trunk is from 40 years. When buying natural material, it is recommended to choose trees from the least boggy location. Otherwise, there is a high risk of buying wood that is rotten inside.

-

The product, which has been treated and impregnated with special compounds, should be kept under a canopy. Make sure that the material is not exposed to sunlight. Under their influence, the product begins to deteriorate and deform, cracks appear.

-

The process of harvesting and processing aspen must be carried out during the period when juicing begins. During this time, the wood is wet, so artificial drying will not deform the sawn timber.

-

The final processing process is carried out at the beginning of March. If you do not adhere to these deadlines, it will be very difficult to process wood with a saw or ax.

-

When working with aspen, experts recommend cutting "in the paw". This option prevents cracking of the material.

-

During the processing of raw materials, it must be covered with an antiseptic. Any other biosecurity option is also suitable.

-

If desired, the wood can be varnished and the material can be impregnated with tinting. This will give it an expressive color.

Review overview

The owners of aspen baths share their impressions with those who are just choosing the material for future construction. Opinions were divided. Some speak positively about this variety, denoting the advantages of aspen. Others believe that there are more profitable counterparts on the market.

Aspen is an expensive lumber. AND in order for the building to be reliable and stand for more than a dozen years, you will have to spend money on carefully selected and processed wood.

See the video about aspen baths.

The comment was sent successfully.