DIY balcony floor

Many people living in apartments need to repair the balcony on their own, from which it follows that the installation of the floor on the balcony should be carried out in the highest quality manner.

Housing prices are very high today, and a couple of square meters on the balcony will definitely not bother anyone, especially if the apartment itself is small. For this reason, special attention should be paid to repairing the balcony and insulating its floor, because the largest amount of lost heat goes through the floor.

Views

Depending on the goals and purpose of the balcony, flooring technologies may be different. There are three main types, each of which differs in the degree of complexity of self-installation:

- flooring - the floor covering is installed on a finished concrete slab;

- potting subsequently covered with ceramic tiles or similar materials;

- wooden floor.

All of the above options allow you to make a warm floor if a heating system is installed in the process. It can be electric or (less often) water.

It should also be noted that unauthorized laying of the heating pipe connected to the central heating is prohibited. To carry out this kind of work, you need to have a special permit, which can be obtained from the architectural supervision authorities.

What can be made of?

There are several types of balcony floors. Like any other floors, they can be wood, tile, self-leveling or polymer. Any kind can be equipped with electric heating (cable or infrared):

- Polymer floors are made from rolls of linoleum (possibly insulated) or from PVC tiles. They can be used both as a stand-alone coating and as a decorative one.

- Self-leveling floors are made from special self-leveling mixtures, which are based on cement or artificial resins.

- Tiled floors are made of tiles or ceramic granite. Not so often, but still, natural stone is also used for their manufacture. The rare use of these materials is due to their heavy weight, which may undesirably affect the balcony slab itself.

- Wood floors are the most popular solution for a balcony, since they are not as heavy as tiles, and at the same time they retain heat better. There are several main types of wood floors: parquet, tongue-and-groove boards, laminated wood.

Any coating, regardless of type, must be resistant to dirt. It also needs to be durable and visually good.

When choosing the type of floor, it is necessary to take into account the design of the balcony. If the balcony is open, then tiles or just a painted concrete slab would be the preferred option. When choosing materials, you need to take into account how much they will be able to withstand all seasonal cycles associated with freezing and thawing. If the balcony is glazed, then almost any type of floor from the previously listed is suitable for it.

Required tools

You may find it useful:

- puncher;

- screwdriver;

- jigsaw;

- hammer;

- roulette;

- dowels;

- drill;

- marker or pencil;

- screws;

- acrylic or silicone sealant;

- cement or glue;

- Styrofoam;

- insulation or thermal insulation coating.

Preparing the slab and base

First you need to check the evenness of the surface of the base of the balcony. This is done using a building level. In the event that the base is not even enough, you must first align it with a screed.

The next steps are:

- The initial stage of installing a balcony floor is to fill the screed. In order for the screed to be even, first of all, you need to solve the problem of leveling the floor. This is done by installing beacons, which are reinforced metal strips. These strips are cut into a number of parts (depending on the size of the balcony) and installed at a distance of 60 cm from each other, perpendicular to the base.

- You need to align the beacons using the building level and a semi-dry solution with which they are fixed. In the event that the balcony is not glazed, a slight slope should be made towards the street. Align all beacons separately. When the work is over, the final alignment should be performed over the entire area.

There is no need to rush, the work must be done very efficiently and accurately.

- When the beacons are fixed and aligned, you need to leave them for a day in order for them to freeze. It is possible to prevent spreading of the solution by performing formwork. To do this, you need a block of wood or a board, which is installed on the outside of the base. The remaining gaps should be covered with a thick solution. When the fill is complete, this formwork can be removed.

- Expanded clay is well suited for screed insulation, which must be placed at the level of the profile, completing the filling with it. You can not be afraid to have time to do this at a time, since the surface is not so large in area. When the floor is poured, you should wait for its final hardening, which will occur in a certain number of days.

- When the floor has hardened, the final finishing can be done. Ceramic tiles can be a suitable material for this finish.

We insulate the floor: step by step instructions

Floor insulation begins with the installation of wooden formwork on it. To do this, you need wooden slats:

- First of all, you need to measure the width of the floor with a tape measure. After that, you need to transfer the measurements to a wooden block using a marker or pencil. When the markings are ready, using a jigsaw, you need to cut off part of the bar of the required length, resulting in a wooden log. It must be attached to the attachment point, after which, with a hammer drill, drill holes in it at the same distance (30-40 cm). This must be done so that the holes are through, because the log will be attached to the floor.

- Then you need to insert the dowels into the holesdrilled in a wooden plank and hammer them into the floor. After that, insert the screws into the dowels and hammer them in with a hammer. The log will thus be attached to the floor.

- When the bar located in the width is fixed, you can take the bar located in the length. It is attached in exactly the same way. The only difference is the spacing between the holes, which can be slightly larger (50-60 cm). Then several more strips located in length are attached, so that a kind of "lattice" is obtained, between the strips of which the foam will be laid.

Installation of foam and second layer of formwork

Stages:

- The polystyrene is cut into plates and placed between lengthwise wooden planks. The width of the foam strips should be about 7-8 cm. For cutting, it is best to use a simple construction knife.After the foam is laid, you should proceed with the installation of the second layer of the formwork, the installation of which is carried out in the same way as the first layer, with the difference that the fastening will be carried out without dowels.

- The wooden planks will no longer be attached to the floor, but to the wooden planks of the first layer. Fastening, thus, will be carried out by means of self-tapping screws and a screwdriver. When the second layer of formwork is ready, pouring should be performed. The prepared solution of cement or glue is applied with a spatula along the inside of the perimeter.

- After filling, you can start installing wooden planks in width. There should be a distance of about 15-20 cm between them, which must subsequently be filled with another layer of foam. When all the planks are installed, you will need to once again eliminate all gaps with cement or glue.

Insulation laying

When the solution hardens, it will be possible to lay insulation. It is important not to be mistaken with the styling side by setting it so that the reflective side is on top. When installing insulation, you must adhere to the following points:

- it must be laid with an overlap, so that the insulation goes on the walls and frame of the balcony by 3-4 cm;

- the remains of the insulation must be rolled back into a roll;

- excess insulation is cut off with a construction knife;

- at the end, it is necessary to straighten and smooth the material so that its surface is even.

When the insulation is laid and spread, it will need to be fixed with wooden logs, the installation process of which has already been described earlier. In fact, now we need to mount another layer of "lattice", between the slats of which another layer of foam will be laid, already the third in a row. The new layer of foam must also be secured on top with another layer of wood planks.

At this stage, the installation of the floor can be completed by sheathing the resulting multi-layer structure with clapboard. Alternatively, for cladding, you can use tightly fitting wooden slats, on top of which the floor covering will be installed. In order for the floor to be more durable, it is also advisable to lay the slats in two layers.

Cold floor coating options: installation steps

Wooden floor

In order to install a wooden floor on the balcony, the surface on which the installation will be carried out must be flat. There are two ways to level the slab:

- knock down irregularities;

- perform a screed.

When the support beams are installed on the flat surface of the slab, you can start installing and painting the crate. In the case when the screed has been perfectly flat, the boards can be installed directly on the screed. However, with this option, the floor will be without insulation, the air in it will not circulate, and it will be quite difficult to fit the boards. The positive side of using boards as a crate lies precisely in the presence of the necessary space for insulation.

In order for the crate to be more durable, it is advisable to paint the boards, or treat them with special compounds that prevent moisture and, as a result, rotting.

The bars are attached to the concrete slab with dowels and self-tapping screws. The crate itself is assembled in the following way: first, a perimeter is made, and then longitudinal or transverse strips are installed at some distance from each other. If the balcony is long, then it is preferable to lay the boards across.

Laminate

Laminate is a fairly popular material for covering the floor on the balcony. The advantage of this material is the presence of several layers that provide:

- rigidity;

- thermal insulation;

- noise suppression;

- moisture resistance.

The top layer of this coating is decorative and contains a pattern. When choosing a laminate as a floor covering on a balcony, it should be borne in mind that this material does not tolerate water very well, therefore, waterproofing is important when installing it.

The surface on which the laminate is laid must be flat, so before installing it, it is imperative to carry out all the relevant preparatory work, such as the screed and installation of the battens.

Between the lathing and the laminate, it is necessary to make a backing layer, the material for which can be polystyrene or cork. This layer should form a 90 degree angle with the laminate. The joints of the fragments of the backing layer must be glued with tape.

It is necessary to install, starting from the side opposite to the entrance to the balcony. There are three options for installing laminate flooring:

- diagonal;

- longitudinal;

- transverse.

Each new row of laminate flooring must be laid with an offset of 40 cm, as this will increase the strength of the coating. In this case, a small (about 10 mm) distance should be left between the laminate and the wall. Laying such a coating is quite easy, since the fragments of the material are installed "in the lock".

Plywood covering

A relatively easy-to-implement version of the balcony floor. As in all other methods, first of all, it is necessary to level the surface of the balcony slab, by doing this with a screed or by knocking down irregularities. Then logs are installed on the concrete base using screws and dowels, which it is desirable to paint.

Next, the plywood sheets are cut according to the length and width of the balcony. It is advisable to cut using an electric jigsaw. This tool will make the edges of the sheets even, and the cutting process itself will be easy and convenient. When installing plywood sheets on the crate, a small gap should be left. This is done so that the floors do not creak later.

In order for the plywood floor to be more durable, it is advisable to lay the sheets not in one, but in several layers. The finished plywood floor can be either an independent coating or a good base on which you can lay linoleum or carpet.

Ceramic tile

Another possible option is to cover the balcony floor with ceramic tiles. This option is also quite simple to implement. You should pay attention to the surface of the tile: it must be textured or rough, but not glossy, otherwise the floor will be slippery.

You can cope with laying tiles on the balcony yourself. For this you will need:

- tile adhesive;

- spatula-comb;

- building level;

- tile cutter or grinder with a disc for cutting stone.

When stirring the glue, be sure to follow the instructions, which are usually written on the package. Tiling begins from the corner opposite to the entrance to the balcony. The glue is applied with a spatula to the concrete slab, then the tiles are placed on top and pressed down. This sequence is repeated for subsequent tiles until the entire floor has been installed. If there are areas in which the whole tile does not fit, it must be trimmed, having previously measured the free space and made markings on the tile. When the glue is dry, all that remains is to clean and rub the seams.

What and how to cover the raised floor

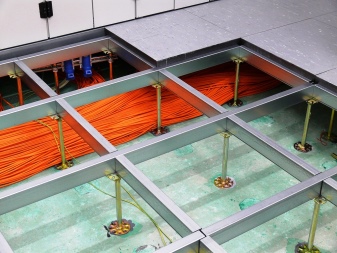

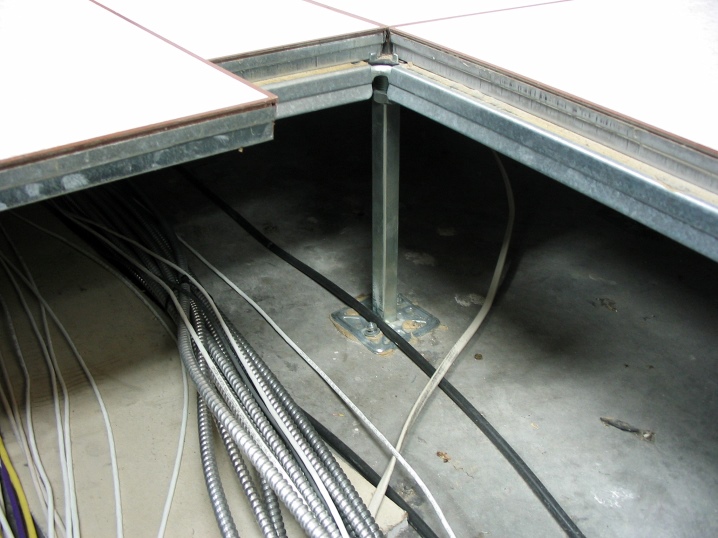

When installing a raised floor (or raised floor) on the balcony, it must be borne in mind that this type of floor can only be installed on a glazed balcony. Installation consists of several steps:

- measuring the balcony and marking the main points of the grid, which will determine the location of the racks;

- installation of raised floor racks and their connection using stingers;

- laying tiles, accompanied by level control and height adjustment;

- final adjustment;

- laying decorative coating.

The slab (or panel) of the raised floor is a flat element that has a square shape.The size of the panels is always mostly the same and is 60x60 cm. The thickness of the panel can be 2.6 cm or 3.6 cm (it depends on the conditions of use of the floor).

All necessary communications are installed in dedicated boxes located under the panels. At the same time, the plates are freely located on the supports, so you can remove the desired plate at any time in order to get to the communications located under it. On the balcony, this may be the communications of the electrical heating system.

There are three types of panels used to install a raised floor:

- high-density chipboard panels;

- calcium sulfate panels with cellulose reinforcement;

- calcium sulphate panels with mineral fibers.

Various materials can be used as a decorative coating for panels, among which PVC, linoleum or carpet can be found most often.

The underside of the slab can be clad with aluminum sheet or steel plate. Steel cladding is commonly used in industrial areas where the raised floor has to withstand heavy loads and traffic. To cover the raised floor on the balcony, a lower cladding with aluminum sheet would be a more appropriate option.

For information on how to make a warm floor on a balcony with your own hands, see the next video.

The comment was sent successfully.