How to make and install a window sill on the balcony?

We are used to using a balcony or loggia as additional premises, whether it be a full room or a storage room for things. During the insulation work, questions arise about the installation of the window sill: how to install it correctly, what comes first and how wide it should be.

Types, purpose and design

The window sill is necessary on the balcony not only as part of the decorative element that completes the entire balcony design. One of the main functions is that the window sill prevents cold air from entering from the outside and does not release warm air from the inside. Another purpose is functionality. After all, you can place indoor plants on it or equip a desktop.

Window sills are divided according to material and shape. According to the last point, they are divided into three types:

- standard models - rectangular table top, both large and small;

- corner - solid table top, which "captures" perpendicularly standing walls;

- combined - such models are most often used when installing a designer canvas - it can be bay window or rolling tabletops.

The table sill most often belongs to the latter category, but sometimes it can also be included in the first group. It depends on how exactly you want to install the countertop. In case a wide table top is stretched along the perimeter of the entire balcony, then this is the first group.

If you decide to install a window sill-table only at the ends or along the perimeter of the larger side, then such models belong to design options.

The design of window sills can be very diverse. You can mount it with a ledge or flush with the wall. In the first case, you will receive a useful area that you can use for your own purposes. Wide models can serve as a full table or a small table for evening gatherings.

It is also possible to use the entire area under the windowsill. For these purposes, boxes are installed below, along the perimeter of a larger wall or only on the end sides. Doors from them can be hinged (if the area of the balcony allows), and a compartment.

In construction hypermarkets, a huge number of models of various colors and textures are presented. The most budgetary option is considered to be white plastic. It will fit any design and will fit into both a budget renovation and an elite one. In terms of texture, they mostly prefer plastic or acrylic wood-like options. Such models are very practical to use and also look very presentable.

Material

As for the material for the manufacture of window sills, today both budget and premium models are presented on the market.

Plastic

PVC models are considered the cheapest. In stores, they are presented in a huge assortment of different lengths and widths. Plastic window sills are very practical to use and are suitable for narrow balconies. However, the color is not limited to white only. Today you can buy plastic models for wood, stone, or just a bright monochromatic color.

The only thing is that the cost of such options will be slightly higher than white plastic.

Models made of such material have many advantages: they are easy to clean, and mold does not appear with constant contact with moisture. In addition, there are no big problems with the installation itself.

PVC models are not resistant to damage, and at high temperatures the plastic begins to melt. Laminated PVC will lose its appearance after a year of use. Such window sills cannot withstand heavy loads, so even washing the windows can be a problem.

Acrylic

Acrylic options are also considered not the most expensive on the market, however, in comparison with plastic models, the price is 2-3 times higher. In addition, the cost of acrylic window sills will increase if you decide to install models with a glossy surface. Also, the price depends on the thickness of the models and the options for edge processing.

Such models are not afraid of mechanical stress, temperature extremes or heavy weight. The advantages also include easy cleaning, seamless connection, lack of porosity, under the influence of the sun, acrylic does not change its color and texture over time.

At the same time, acrylic does not withstand too high temperatures - therefore, traces may remain on the windowsills.

A natural stone

The more expensive option is considered to be made from natural stone. The average cost of one running meter starts from 4-6 thousand rubles. These models are most suitable for finishing balconies in luxury homes. But do not forget that not every balcony is able to withstand a heavy structure.

Most often, stone options are made from natural marble and granite, as well as artificial agglomerate. The surface of such models is made in several versions: polished, polished or aged. When installing models made of natural stone, you will also have to spend money on special profiles, the cost of which starts from 1,500 thousand rubles.

Wood

It is better to refuse the installation of wooden models if your balcony is not insulated or heated:

- First, when exposed to moisture, the tree will rot

- Secondly, due to sudden changes in temperature, the tree dries up and loses its original appearance.

If you nevertheless decided to install a tree on the balcony (and made the balcony warm), then treat the window sill with special means - moisture-resistant impregnations. Thanks to them, you can avoid large deformation.

Also pay attention to the installation of such models. It is the wood options that are considered the most difficult to install. When installing, it is necessary to take into account the fact that the tree is prone to deformation not only due to external factors, but also due to internal ones - the temperature in the apartment, the level of humidity.

MDF or chipboard

Only a window sill made of MDF or chipboard will cost less than wooden models. Models made of MDF are much stronger than DPS. In addition, the latter uses harmful formaldehyde resins. It is better to purchase a board laminated on both sides. When cutting, the end parts of the window sill are best protected with a plank so that moisture does not disturb the appearance of the board.

Chipboard models, although the cheapest, are very impractical. Such window sills do not withstand heavy loads and will only serve as an aesthetic part of your balcony. In addition, both materials will have to be coated with a special impregnation, and the work itself is repeated once a year.

The size

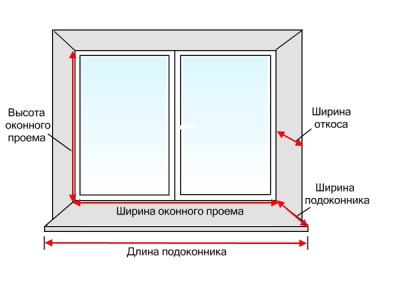

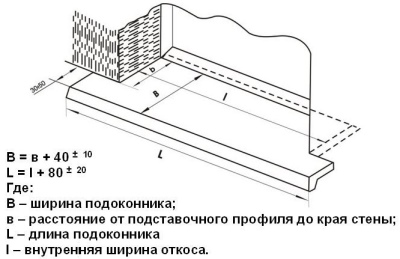

To determine the correct length measurement, you need to measure the width of the window opening. Add 6-10 cm to the resulting figure. As a result, you should get the ledges of the window sill on each side of the slopes. The minimum projection size is 3 cm.

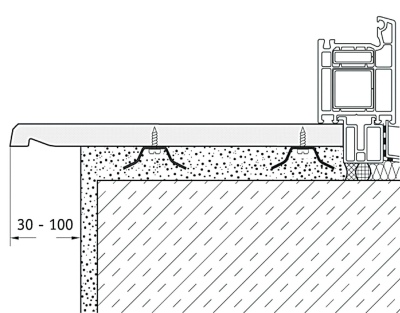

On the balcony, window sills are cut into the wall on one side. At the door, they should protrude one centimeter. When calculating the width, add 2 centimeters to the total figure - this is exactly how much will be required for the spade under the windows. This spade is necessary so that the windows on the balcony do not fog up.

The ledge on the balcony must be made according to your wishes. The best option is 5 centimeters. If you want to use the window sill as a working area, then the ledge can be from 7 to 20 centimeters.However, do not forget that if the protrusion is large, it will be necessary to install special brackets for stability.

Also, when working, you can use the formula to calculate the length and width of the window sill.

How to do it yourself?

For this work, you need to know not only the dimensions, but also the specifics of the premises: average temperature, humidity, and the possibility of heating.

When installing the window sill, also take into account the protrusions of the frame. Sawing must be done with a hand jigsaw (when it comes to wooden or PVC models) or a grinder with a special saw (for acrylic and stone). It is important to understand that all materials are quite fragile and one awkward movement can ruin the whole work.

Installation options

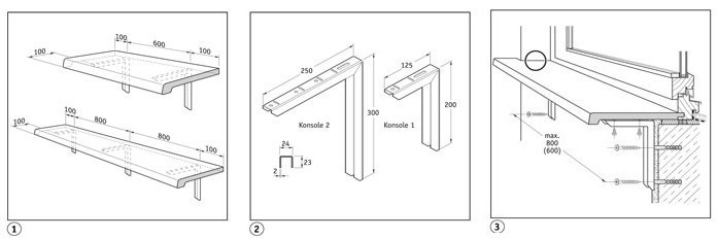

Before installation work, you must choose one of the mounting options: using brackets, on mounting foam or glue, on retaining brackets.

Most often, window sills on balconies are installed using brackets. This ensures that the entire structure is retained despite external influences. But in some new houses today, installation on brackets is not possible due to the fact that the balcony frame may not withstand the load. In such cases, repairmen attach the window sills to the foam.

Installation on brackets

There are 4-5 brackets for every meter of the window sill length. They can be installed on a concrete or brick wall or on a special aluminum profile. The brackets are being mounted on self-tapping screws for concrete. The canvas is laid after mounting the brackets. Then the canvas is installed to the window using screws.

Installation on polyurethane foam

- In the first step, you place liners under the canvas. It can be a wooden block.

- Then you lay the canvas, securing it with polyurethane foam. Do not forget to use the building level when working.

- Next, you install the brackets on which the rest of the canvas will go.

- Then, thanks to the load, the window sill is pressed against the base.

- The slots are filled with foam, and the structure itself remains in this position for 2-3 days.

Bracket mounting

This type of installation is only possible with a large base space - a concrete or brick wall. Special staples are available from hardware stores. When installed, the canvas is evenly superimposed on the base and fixed to the staples.

Before starting the installation process of the window sill, the balcony surfaces must be cleaned of dust and dirt. It is advisable to walk with a sealant along the joint between the window and the wall.

In more detail about how to install a window sill on a balcony, the following video will tell.

The comment was sent successfully.